Why Use Aluminum Foil Side Gusset Bags for Food and Coffee Packaging?

In industries like food and feed, packaging remains a key factor in ensuring consistent quality and market competitiveness. Traditional plastic and woven bags are prone to damage, moisture, and leakage during distribution, which can shorten product shelf life, compromise flavor, and even impact consumers' sense of security and the brand's professional image. Faced with increasingly fierce market competition, companies urgently need packaging solutions that balance barrier performance, display appeal, and brand value.

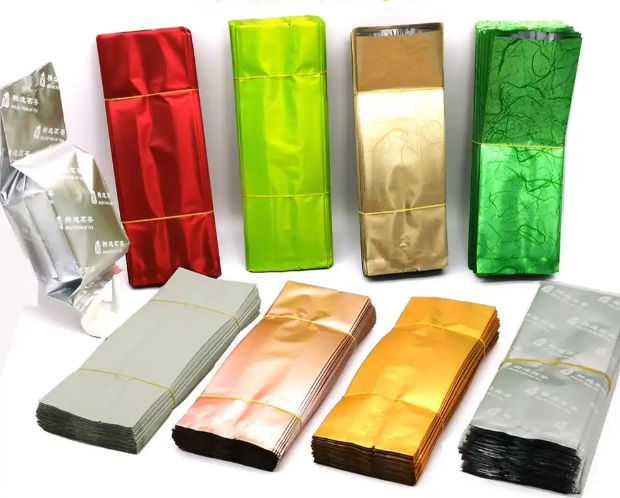

Against this backdrop, aluminum foil side gusset bags have emerged as a leading example of high-performance packaging. By laminating aluminum foil with various functional films and adding accordion pleats on both sides, they not only address the shortcomings of traditional packaging in terms of moisture and oxidation resistance, as well as load-bearing capacity, but also provide greater capacity, a more stable three-dimensional effect, and a wider display space. From coffee beans to pet food, aluminum foil gusset bags, with their superior sealing and structural design, help maintain consistent product quality in the complex environments of storage and transportation.

As a specialized provider of customized, flexible packaging, MTPAK boasts a mature technical team and rigorous quality control, providing tailored aluminum foil gusset bag solutions to meet the specific needs of various industries and products. Whether it's coffee, tea, nuts, or even animal feed and pet food, MTPAK helps companies extend product shelf life while achieving more effective brand presentation and competitive differentiation.

What is an aluminum foil side gusset bag?

From a structural definition, the aluminum foil side gusset bag is a self-supporting packaging bag that is made by combining aluminum foil with other functional films (such as PET, NY, PE/CPP) through dry lamination or solvent-free lamination, and innovatively adding accordion pleats (Side Gusset) on both sides.

What are the advantages of aluminum foil side gusset bags?

1.Material Foundation: The Synergistic Effect of Multi-Layer Composites

l Core Barrier Layer: Aluminum foil itself is the cornerstone of barrier properties. Its metallic crystal structure effectively blocks light, oxygen, water vapor, and odors. This forms the physical foundation for long-lasting freshness preservation.

l Outer Protection Layer: Typically made of high-strength, abrasion-resistant polyester (PET) or nylon (NY), it protects against the physical friction and impact of transportation and display, and serves as a substrate for high-quality printing.

l Inner Heat Seal Layer: Materials such as polyethylene (PE) or cast polypropylene (CPP), which comply with food contact regulations, are used to ensure a stable and tight heat seal on the packaging bag, preventing leakage at the sealed edge. For even higher barrier requirements, we embed high-barrier resins such as EVOH (ethylene vinyl alcohol copolymer) into the composite structure to maximize oxygen barrier performance.

2.Functional Design: The Wisdom of Three-Dimensional Sides

l Self-Support and Stability: The accordion pleat design ensures the bag stands firmly even when empty or lightly filled, significantly optimizing shelf display and enhancing brand image.

l Space Utilization and Capacity: The expandable side panels allow the bag to adapt to space during storage and transport. When unfolded, it offers a larger capacity than conventional flat-bottom bags, improving logistics and warehousing efficiency.

l Enhanced Physical Strength: The three-dimensional structure disperses the pressure of the contents on the bag's sides. Combined with rigorous heat-sealing process control, the bag's overall resistance to pressure and blasting is significantly enhanced.

What products can aluminum foil side gusset bags protect?

Coffee Beans and Ground Coffee

Coffee products are extremely susceptible to the effects of oxygen, moisture, and light. Oxidation causes coffee beans to lose their aromatic oils, resulting in a decreased flavor. The low OTR (oxygen permeability ratio) and low WVTR (water vapor permeability ratio) of aluminum foil significantly slow this process. Combined with a one-way degassing valve, it also allows carbon dioxide released after roasting to escape, preserving optimal flavor.

Tea and Herbal Drinks

Tea can easily deteriorate due to moisture and light exposure, especially high-end teas, whose aroma and color depend on a stable storage environment. The light-shielding and airtight properties of aluminum foil gusset bags effectively prevent the tea from mold and aroma loss, ensuring consumers can enjoy the full brewing experience.

Nuts, Dried Fruit, and Snacks

Nuts are rich in oils and are easily oxidized, resulting in a rancid flavor. Dried fruits easily absorb moisture and become soft. Using aluminum foil gusset bags not only slows down fatty acid oxidation but also prevents moisture absorption during distribution, ensuring a consistent taste and texture. This is particularly critical for export brands.

Grains, Flour, and Seasonings

Moisture or contamination during the transportation and storage of flour, rice, or protein powder can directly impact the quality and safety of these products. The barrier effect of aluminum foil and the stability of gusseted bags ensure that these powders remain dry and safe during long-distance transportation and high-humidity environments.

Pet food and specialty nutritional supplements

These products typically require high packaging volumes and long shelf lives, placing higher demands on packaging strength and sealing. Aluminum foil gusset bags not only provide a long-term barrier but also enhance compression and puncture resistance through thickened material, ensuring protection from damage during storage and transportation.

In summary, whether it's coffee and tea that need to preserve their flavor, or nuts, powders, or pet food that require a long shelf life, aluminum foil gusset bags offer stable and reliable protection. This is a key reason for their widespread adoption across various industry segments.

What common mistakes should you avoid when choosing aluminum foil side gusset bags?

Myth 1: All aluminum foil bags are created equal.

Fact: Barrier performance and strength depend on the foil thickness (in μm), the compound material, and the process. We recommend the appropriate compound material based on your product's characteristics (such as acidity, alkalinity, and oil content) to ensure compatibility and safety.

Myth 2: Focus only on the bag, not the seal.

Fact: Heat seal strength directly impacts overall barrier effectiveness. The heat seal temperature and pressure are typically precisely controlled to ensure a tight, smooth seal and avoid leaks at the edges.

Myth 3: Environmental attributes are ambiguous.

Fact: The recyclability or sustainable sourcing of materials should be clearly defined. While recycling traditional aluminum-plastic composite bags presents challenges, options are now available that use sustainably sourced materials (such as FSC/PEFC-certified paper) laminated with aluminum foil.

Conclusion

As you can see, aluminum foil side gusset bags are increasingly popular with food companies and brands due to their excellent barrier properties and unique design. They can meet the packaging needs of a wide range of products, from coffee beans, tea, and nuts to cereals and pet food.

MTPAK, a provider of custom flexible packaging solutions, offers a wide range of customized services. Our standard flexible packaging series and eco-friendly series provide proven products for diverse markets. We can also customize our products with a wide range of shapes, sizes, thicknesses, coatings, materials, and additional features to create the perfect custom packaging solution.

Want to learn more about aluminum foil gusset bag solutions? Contact our expert team for support.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak