25kg Rice Bags Guide: Materials, Types & Cost Factors

Most people don't pay much attention to rice bags. But when you're moving tons of grain from mills to ports, the right 25kg bag matters. It needs to be tough, keep water out, and still make economic sense. At MTPak, we've supplied these bags to rice processors and exporters for years. Our bags are built for real handling — they don't fail when stacked high or shipped overseas.

This guide walks through material choices, bag types, and cost factors for 25kg rice bags. You'll see how to match the bag to your operation.

Why Has the 25kg Rice Bag Become the Global Standard?

The 25kg bag works well for bulk handling. It's a weight one person can still move, but dense enough to ship efficiently. You'll find this size across food aid programs, wholesale markets, and export goods. While traditional 25kg bags often use woven polypropylene, modern operations are shifting to flexible packaging. MTPak focuses on this shift—we supply laminated film bags that handle the same weight while offering better moisture barriers and print quality. We adjust the material specs based on the destination, like using FDA-compliant films for the U.S. market.

What's the Basic Process for Packaging Rice?

There are a few important phases that most packaging lines go through. First, weighing — multi-head scales or volumetric cups give exact amounts. Then, putting things in bags, either using bags that are already produced or making them from roll stock. Finally, sealing — for retail bags, heat sealing; for industrial bags, sewing. MTPak helps customers choose the right equipment according to how much they need to produce. For smaller operations, we help with semi-automatic lines, and for larger operations, we recommend full automation.

Which Packaging Material Suits Rice Best?

Material selection balances protection, cost and sustainability. Here's how common options compare:

| Material Type | Advantages | Limitations |

|---|---|---|

| Jute/Cotton Bags | Biodegradable, breathable | Poor moisture barrier, heavy |

| Woven PP Bags | Strong, moisture resistant | Not biodegradable |

| Laminated Films | Excellent barriers, good print quality | Hard to recycle |

| Multi-layer Plastic | Good sealing, customizable | Less eco-friendly |

In practice, packaging choice depends on balancing cost, protection, and market requirements. For retail and premium rice, multi-layer laminated pouches are gaining ground. They handle the job while offering superior printing and barrier properties. Two features often determine which way customers go.

Moisture and Barrier Protection

High humidity ruins rice fast. Stand-up pouches and gusseted bags with low water vapor transmission rate (WVTR) linings keep grain dry. The right film structure blocks moisture and odors effectively. MTPak uses laminated layers in our pouches to achieve this, ensuring they meet EU and FDA food contact standards.

Custom Printing and Shelf Impact

A plain bag holds rice, but a well-printed one builds your brand. Multi-color graphics make products stand out in crowded retail environments. We produce sharp, durable designs using HD flexo printing with water-based inks. More colors and complex designs do increase the unit cost—clean, efficient layouts help manage the final price.

What Are the Different Types of Rice Bags and Their Features?

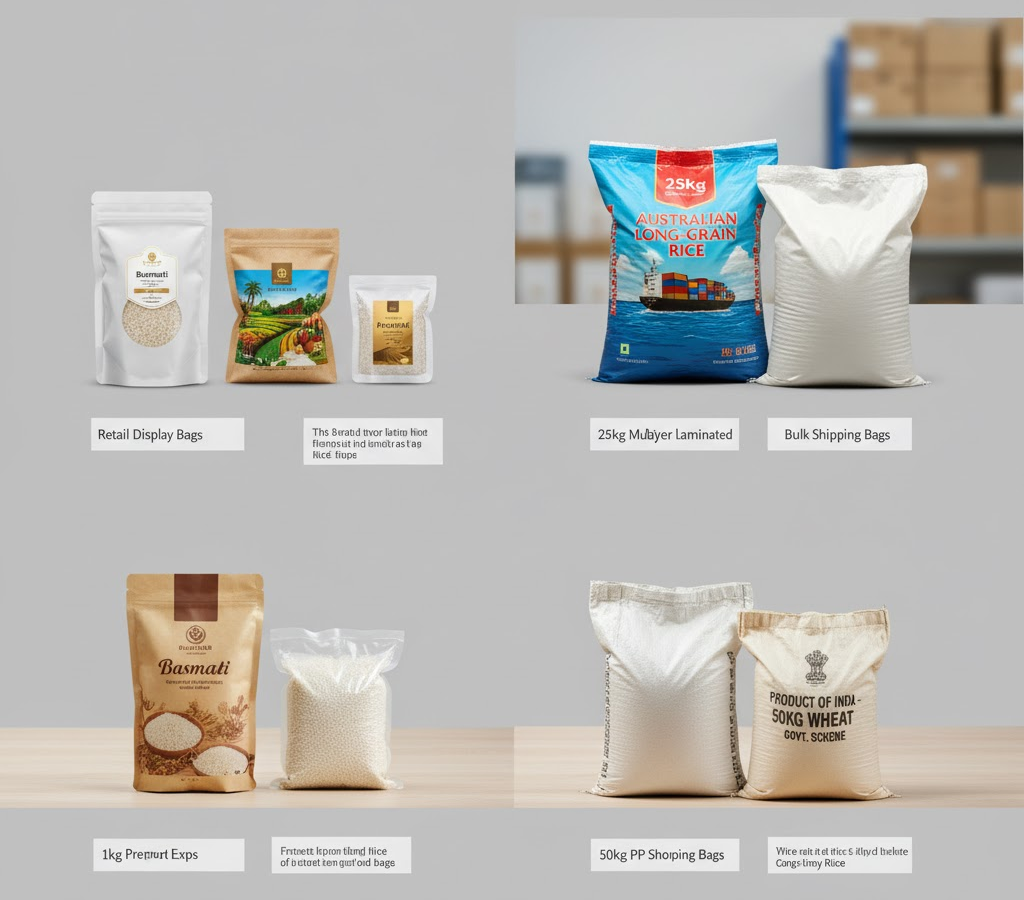

Bag design directly affects both function and market positioning. Different structures work for different weight ranges and sales channels. The bag's shape tells you a lot about where it will end up — supermarket shelves need one approach, shipping containers need another. Here's how common rice bag types break down:

| Bag Type | Common Use & Weight Range | Key Features |

|---|---|---|

| Stand-up Pouches | Retail(500g-5kg) | Good shelf presence, resealable options, high-barrier films |

| Gusseted Bags | Retail/Small Bulk (1kg – 10kg) | Side folds increase capacity, display well, efficient material use |

| Vacuum-sealed Bags | Premium/Export (500g – 5kg) | Removes air to prevent oxidation and pests, maximizes freshness |

| Flat Bottom Pouches | Retail(1kg-5kg) | Box-like structure stands upright, five printable panels |

| Multi-layer Laminated Bags | Bulk (10kg – 25kg) | Strong structure with high-barrier films, good print quality |

| PP Woven Bags | Heavy Bulk (10kg – 50kg) | High strength, tear-resistant, cost-effective |

MTPak specializes in flexible packaging for rice, focusing on retail-ready solutions. Our stand-up pouches and gusseted bags use multi-layer laminated films—materials like PET/PE provide good rigidity for shelf presence while sealing tightly. These bags handle the knocks of shipping while keeping rice fresh.

Retail Display Bags for Smaller Rice Packs

When you’re packing smaller portions of rice for supermarket shelves, the stand-up pouches and flat bottom bags are what actually work in the real world. They don’t just look neat – they physically stand upright by themselves on the shelf, which means you can fit more packs in the same space without them toppling over. We make these stand-up rice pouches with a proper zipper reseal that customers can open and close over and over again. It’s not some flimsy seal that breaks after one use; it actually keeps the rice fresh every time you open the pack to scoop out a bit more.

Bulk Shipping Bags for Export Markets

Shipping rice overseas? You’re dealing with pallets stacked sky-high, long hauls across oceans or continents, and constant jostling. We engineer them to shrug off the crushing weight of stacked pallets without splitting at the seams or bursting open when things get rough.

The construction is all about survival: reinforced seals that lock in place so tight, they won’t wiggle loose no matter how many times the shipment shifts or bumps against other cargo. And those barrier films? They’re not generic plastic – they’re specially formulated to actively repel moisture.

This isn’t a “good enough for most of the trip” solution. From the second the bags leave the factory loading dock to the moment they hit the receiving warehouse overseas, every layer is designed to protect the rice like it’s our own cargo.

How Do You Match Bags to Different Applications?

These bags serve various users. In South Asia, they're used in government food distribution. In Europe and North America, they're common in retail and wholesale chains. MTPak customizes bags with different closures — stitched or heat-sealed — for everything from Basmati to long-grain varieties. Different applications demand different approaches.

Export and Retail Packaging

Export bags face long sea voyages and changing climates. They need to pass ISO drop tests and often include UV protection. For retail, good printing helps products stand out. We recently supplied an Australian exporter with UV-coated bags that held up through months of storage and shipping.

Government and Agricultural Programs

Here, low cost and durability come first. Bags are usually simple, with single-color printing or none at all. MTPak's economy line uses lighter materials and standard stitching to keep prices down while still carrying heavy weights.

How Do You Evaluate Packaging Costs?

Look past the price per piece. Factor in material thickness, order quantity, and special barriers. Larger orders drop the unit cost. At MTPak, we review the full picture—a stronger coffee bag might cost more upfront but prevents spoiled product losses later.

Material and Production Expenses

Thicker films cost more but withstand rougher handling. A metalized barrier raises the price but protects against moisture. We find the balance between protection and budget.

Logistics and Inventory Factors

Lighter materials reduce shipping fees. Efficient production runs prevent excess inventory. Our flexible scheduling helps importers handle seasonal peaks without overstocking.

What Sustainability Trends Are Changing Rice Packaging?

The industry is shifting toward circular solutions. You see more recycled content, lighter bags, and even return systems. EU single-use plastic rules drive much of this change. These upgrades cost more upfront, but high-volume production eventually lowers the price. Here are the main changes:

Circular Economy and Recycling Systems

Returnable bag initiatives are now used in several areas. Multi-trip designs help reduce waste.

Regulatory and Consumer Pressure

New rules say that bags must be made of recyclable or recycled materials. Getting certified costs extra, but it makes customers trust you. We make bags that fulfill international requirements so that our clients stay in compliance.

Conclusion

Pick 25kg rice bags based on how strong the material is, how well it blocks things, and how it affects the environment. The bag needs to keep moisture out, clearly show your logo, and fit inside your production budget.

At MTPak, we build flexible packaging for rice producers. Our bags use FDA-approved liners for US exports and custom dimensions for local markets. We offer recycled and compostable materials that still block oxygen and moisture. The focus is on reliable delivery and consistent performance for mills and distributors.

Contact MTPak to review your rice packaging needs. We'll provide a clear quote and technical support.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak

FAQ

1. What's the price range for standard 25kg rice bags?

Standard bags run $1-5 each. Custom printing, barriers, or lamination add cost. Larger orders reduce the per-bag price.

2. How do moisture-resistant bags help in humid climates?

Bags with low WVTR liners block humidity. This prevents mold growth in tropical storage conditions.

3. Are there certified eco-friendly options available?

Yes. We offer recycled PP and compostable materials. These meet FDA and EU food contact standards.

4. How to ensure FDA/EU compliance?

We use food-grade materials and test to international standards. Compliance documentation comes with every shipment.