Which Is Better for Food Packaging: PP Material or Polyethylene, and How to Decide?

In the field of flexible food packaging, polypropylene (PP) and polyethylene (PE) are the two most widely used substrates, accounting for over 70% of the food packaging market. For food brands, bakeries, and e-commerce direct-to-consumer companies, choosing the right PE and PP materials not only ensures food freshness and safety, but also reduces packaging costs and enhances the consumer experience.

As a flexible packaging supplier, MTPAK has customized packaging bags in a variety of materials for hundreds of food and coffee brands, accumulating extensive experience in material selection.

This article will examine the core differences between materials and, based on the specific needs of food packaging scenarios, provide a scientific selection approach to help you precisely match food characteristics with packaging materials.

What is the difference between PP material and PE material?

Polyethylene is a thermoplastic resin formed by the polymerization of ethylene monomers. Commonly known as LDPE and HDPE, depending on density, are polypropylene. Polypropylene, on the other hand, is a thermoplastic formed by the polymerization of propylene monomers.

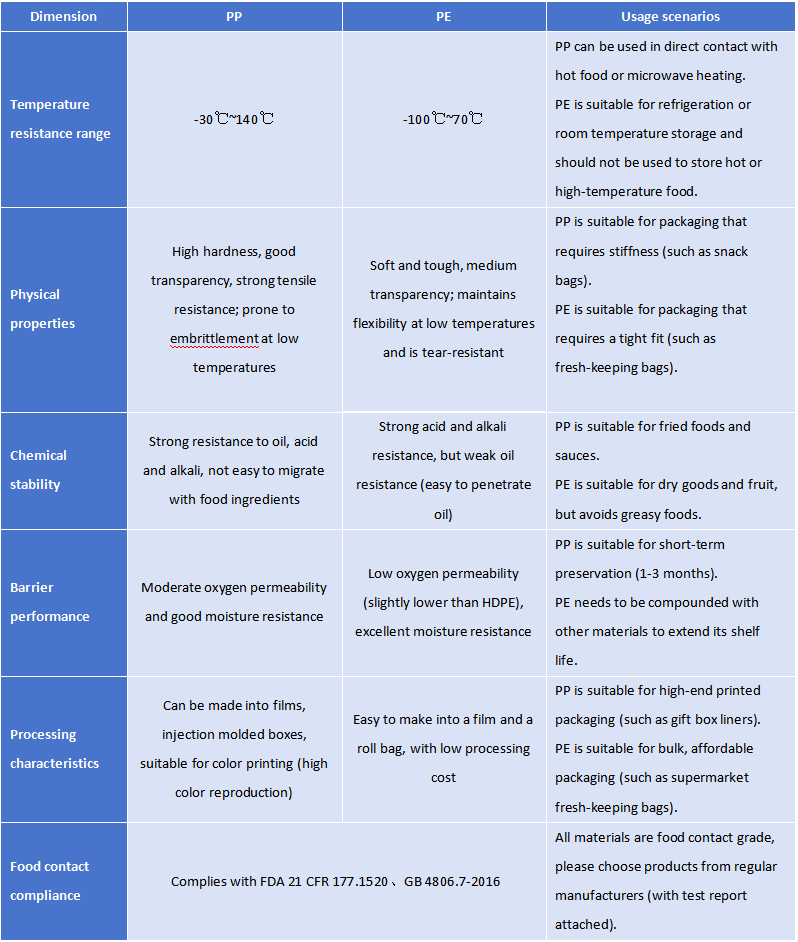

PP and PE both belong to the polyolefin family of plastics, but due to differences in their molecular structures, they exhibit significant differences in temperature resistance, physical properties, and applicable scenarios. These differences directly determine their application limits in food packaging.

The following 6 key dimensions will help you quickly distinguish:

How to choose MTPAK food packaging bag materials?

When choosing between PP and PE, the key factors to consider are the food's temperature requirements, storage cycle, and morphological characteristics. Avoid a one-size-fits-all approach. The following provides specific selection options for four common food scenarios:

1. Hot food/heating scenario: PP material is preferred

Applicable foods: cooked food takeout (such as fried chicken, hot soup), microwave-heated food, baked goods, etc.

If you are using it to hold this type of food, it is recommended to choose pure PP film bags or composite plastic bags, and you need to confirm whether the packaging is marked "microwave safe" and avoid using bags made of recycled PP materials, because such bags may contain impurities and are risky to use at high temperatures.

2. Frozen/low temperature storage scenario: PE material (especially LDPE) is preferred

Applicable foods: frozen meat, quick-frozen dumplings, ice cream, low-temperature yogurt, etc.

It is recommended to choose low-temperature resistant LDPE bags or composite plastic bags.

3. Normal temperature dry goods/snacks: select as needed

Applicable foods: biscuits, nuts, cereals, rice, flour, etc.

If you need to showcase the complete appearance of food to increase purchasing desire, choose PP plastic bags. If you prioritize low cost and are suitable for bulk packaging with a higher load capacity, choose HDPE plastic bags. If you simply need to seal and prevent moisture, whether you choose PP or PE, we recommend resealable zipper bags.

4. Oily/sauce foods: PP material or composite bags are preferred

Applicable foods: fried potato chips, spicy strips, sauce packets (such as ketchup, salad dressing), etc.

It is recommended to choose an oil-proof coated composite bag that meets food-grade standards and avoid using pure PE bags to package heavily oily foods. If costs are limited, you can choose HDPE bags that have been treated with an oil-proof process, but their oil-proof effect will be slightly inferior to that of PP bags.

What are the key points in choosing MTPAK food packaging bags that are easily overlooked?

1. Consider both the material and the compliance

Regardless of the material, the packaging used for food must bear a clear label indicating "food contact use". If necessary, suppliers are required to provide relevant testing reports to prove that the labeling is authentic and not falsified. This is for the sake of your business as well as the health of your consumers.

2. The thickness of the packaging bag needs to match the food requirements, and it is not necessarily the case that thicker means better quality

Generally speaking, the thicker the PE layer, the better the sealing performance. However, blindly choosing a thicker model will only increase costs. It is recommended to select the appropriate thickness according to your needs. For example, a 4-mil thickness is more suitable for packaging bags containing coffee powder, while a 5-mil thickness is more suitable for packaging bags containing coffee beans.

3. Do not confuse high temperature markings with microwave markings

Some PP bags that use aluminum foil or aluminumized film (such as nut bags) cannot be heated in the microwave; otherwise, sparks will be generated, causing a fire hazard.

Conclusion

Polypropylene and polyethylene materials don't have absolute advantages; they only have specific application scenarios. For food companies, precisely matching the characteristics of food and packaging bag materials not only ensures food supply but also enhances product competitiveness through packaging.

If you are considering using MTPAK's products for your company's coffee, nut, cereal, or other food packaging, please feel free to contact us. We are always ready to assist you in fulfilling your needs.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak