Where to Buy Rubber Bands for Packaging?

In the packaging industry supply chain, attention often focuses on bag styles, film materials, and printing, while the most minute, fundamental, yet indispensable components are easily overlooked. The rubber band is one such underestimated player – seemingly simple, yet it plays a key role in bundling, securing, sorting, and displaying products.

Historically, rubber bands were often categorized as stationery or general consumables. However, as the packaging industry evolves towards greater refinement, automation, and sustainability, brands are beginning to re-evaluate this small but highly efficient material: Can it enhance packaging efficiency while simultaneously conveying a professional brand image?

MTPAK has long provided customized flexible packaging solutions for food, coffee, and retail brands. Through our collaborations with clients, we've observed a growing trend of businesses viewing rubber bands as an integral part of the packaging system – not just for securing and displaying products, but also as an element of supply chain management and brand experience. Consequently, selecting the appropriate rubber band material, type, and supply channel is becoming a new focal point within the industry.

Why does rubber band material determine packaging performance?

The performance of a small rubber band extends far beyond mere "elasticity." The composition ratios and processing methods of different materials determine their resilience, durability, and environmental attributes.

Natural Rubber remains the dominant material. Sourced from latex, it offers exceptional elasticity and stretch recovery, maintaining stable deformation through repeated use. This makes it particularly suitable for scenarios demanding high tension, such as in food, agricultural products, and logistics packaging. With tightening environmental regulations, some brands are shifting towards Synthetic Rubber and biodegradable hybrid materials to enhance temperature resistance and reduce environmental impact.

For instance, coffee roasters often select heat-resistant rubber formulations for packing products that are still warm post-roasting. Stationery brands might prefer sulfur-free, odorless natural rubber to ensure no marks are left when sealing paper-based products. The choice of rubber bands by different brands increasingly reflects their understanding of product safety and brand responsibility.

What types of rubber bands are available, and how do they suit different packaging needs?

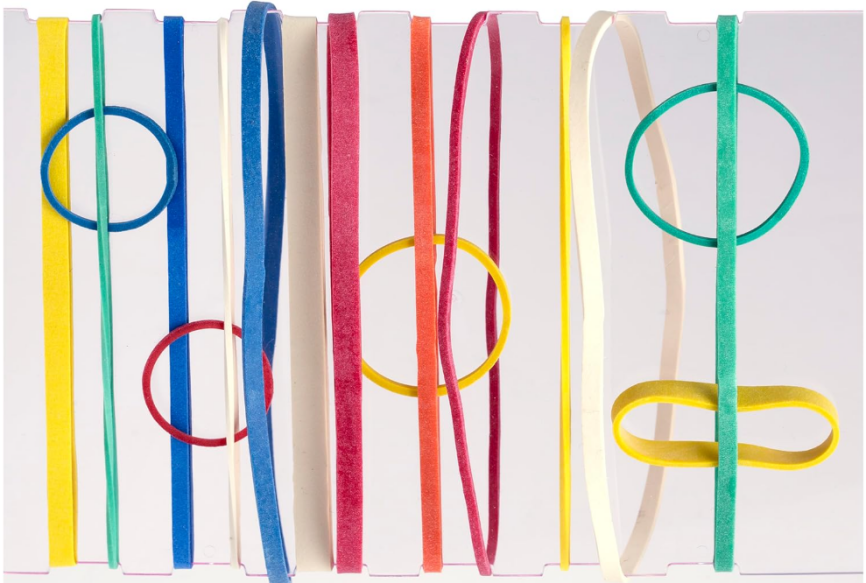

While seemingly basic, rubber bands are no longer uniform "loops of rubber." The evolution of the packaging industry has driven advancements in its material ratios, structural design, and surface finishes. Different types of rubber bands serve varying packaging scenarios and functional objectives.

In logistics and the food industry, high-elasticity round rubber bands remain mainstream. They maintain rebound resilience and consistent tension under frequent use, ensuring bagged or boxed products do not loosen or deform during transit.

For brands in sectors like cultural & creative goods, specialty coffee, and artisanal baking, where visual experience is paramount, Flat Bands are often preferred. Their wider surface area and gentler tension prevent marking or indentation. They also blend naturally with paper labels or kraft paper bags, fostering a "handcrafted" packaging aesthetic.

Wide Bands are typically used for larger products or bundled packaging, such as bags of grains, folders, or e-commerce apparel shipments. Their tension is distributed more evenly, effectively reducing damage caused by excessive pressure on edges.

In recent years, Color-coded Bands have emerged, widely used in warehousing, wholesale, and retail display contexts. Colors differentiate product batches, specifications, or sales areas, enhancing supply chain management efficiency.

Simultaneously, to meet sustainability trends and high-end customization demands, Textured Bands and Silicone Bands have entered the market. The former offers enhanced anti-slip properties, ideal for packaging bottled goods, jars, or glass containers. The latter boasts properties like heat resistance and UV resistance, making them particularly appealing to brands in tea, fragrance, and health supplements.

In some brand packaging, rubber bands have even been elevated to a "design language." For example, a coffee brand might use a wide brown band to secure an information card, conveying a sense of nature and craftsmanship. A stationery brand might use brightly colored bands to cross-bind gift boxes, creating a highly recognizable visual focal point.

From function to aesthetics, from bulk packing to brand presentation, the diversification of rubber band types represents a subtle yet crucial avenue for enhancing experience within the packaging industry.

What new value can rubber bands bring to packaging design?

Excellent packaging is never just about a single material; it's a system supported by multiple components working in concert. The rubber band, though small, perfectly fills the gap in packaging "flexibility."

In displays for coffee, baked goods, or retail products, rubber bands can serve not only as closures or fasteners but also as extensions of visual design. For instance:

In artisanal bakery brands, a light brown rubber band wrapped around a kraft paper bag adds a vintage feel and highlights the brand's natural, eco-friendly ethos.

In premium stationery brands, colored rubber bands become detailed accents securing products and brand cards, adding layers to minimalist packaging.

In bulk shipping operations, reusable, high-strength rubber bands help brands reduce reliance on tape and plastic, lowering costs and carbon emissions.

The rubber band is no longer merely a functional tool; it has become a "small symbol" conveying brand philosophy.

Can rubber bands become more sustainable amid environmental trends?

Amid the wave of green packaging, rubber band production is also undergoing transformation. Traditional rubber, once used for its high sulfur content and difficulty degrading, is gradually being replaced. Now, biodegradable natural rubber, bio-based synthetic materials, and recycled rubber blends are becoming industry standards.

These new materials maintain elasticity while being capable of natural decomposition under specific conditions, reducing the environmental burden of packaging waste. Some brands are even adopting carbon-neutral production methods and low-VOC (volatile organic compound) dyes to minimize energy consumption and pollution emissions during manufacturing.

Much like the trend towards eco-friendly coffee bags, the future rubber band is poised to be not just a tool, but a manifestation of corporate responsibility.

Conclusion

In today's packaging industry, which strives for a balance of high efficiency and environmental consciousness, rubber bands have transcended their traditional role as mere "accessories." They represent the flexibility of packaging systems, the precision of supply chains, and a brand's commitment to detail and sustainable principles.

If you are searching for high-quality, customizable, and environmentally conscious rubber bands or other packaging auxiliary materials, MTPAK is your reliable partner. We offer comprehensive solutions—from material consultation and custom design to production and supply—helping brands demonstrate professionalism through meticulous attention to detail.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak