What’s the Difference Between Double-Sided Adhesive Tape and Regular Tape?

When it comes to product packaging, every layer matters—from the box that protects the contents during shipping to the tape that holds it all together. While most people are familiar with regular packaging tape, double-sided adhesive tape plays an entirely different role in the packaging process.

Both may look similar at first glance, but their structures, materials, and applications vary significantly. Understanding these differences is essential for brands that want to balance cost, functionality, and presentation.

In this guide, we’ll take a closer look at what makes double-sided adhesive tape unique, how it differs from traditional tape, and why it’s becoming an indispensable tool in modern packaging solutions.

What Is Double-Sided Adhesive Tape?

Double-sided adhesive tape is a pressure-sensitive tape that has adhesive applied to both sides of a carrier or backing material. Unlike regular tape—which seals boxes or envelopes from the outside—double-sided tape is designed to bond two surfaces together from within.

Typically, it consists of three layers:

l A carrier (such as paper, foam, film, or cloth) that provides structure and flexibility.

l Adhesive coating on both sides of the carrier.

l A release liner, which protects the adhesive until it’s ready to be used.

Once the liner is peeled off, both sides of the tape can adhere surfaces together without any visible residue or external marks. This makes double-sided adhesive tape ideal for applications that require a clean, seamless appearance—for example, mounting labels, attaching product samples, or securing decorative elements in luxury packaging.

At MTPAK Packaging, double-sided adhesive tapes are often used to attach inner linings or resealable closures in flexible coffee pouches, tea bags, and food-grade packaging, helping brands maintain both functionality and visual appeal.

What Is Regular Packaging Tape?

Regular packaging tape—often simply called “tape”—is what most people use to seal shipping cartons, envelopes, or product boxes. It usually has one sticky side coated with a pressure-sensitive adhesive and a non-adhesive backing made from polypropylene (BOPP), PVC, or paper.

Common types include:

l BOPP packing tape: Durable, clear or brown, and used widely in logistics and e-commerce packaging.

l Paper tape: Eco-friendly and recyclable, often reinforced with natural rubber adhesive.

l PVC tape: Resistant to moisture and temperature changes, suitable for long-distance shipping.

Unlike double-sided adhesive tape, regular tape provides external sealing—it keeps packaging closed and protected during transit. It may also carry branding elements, such as printed logos or color-coded labels, serving as both a security feature and a marketing tool.

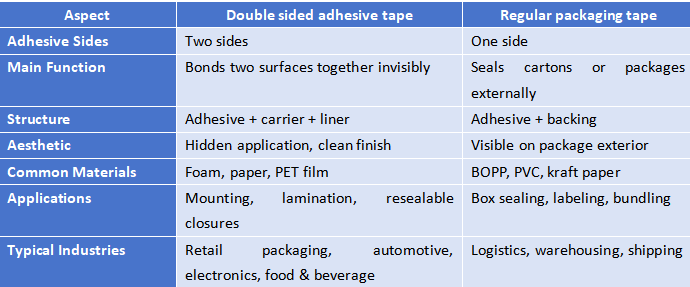

Key Differences Between Double-Sided Adhesive Tape and Regular Tape

Though both products fall under the same “adhesive tape” category, their design purpose, structure, and use cases are fundamentally different.

In essence, double-sided adhesive tape is for bonding, while regular tape is for sealing. Both are indispensable in packaging, but they serve different points in the process—one focuses on internal assembly, the other on external protection.

How Double-Sided Adhesive Tape Enhances Flexible Packaging?

In modern packaging design—especially for flexible materials like pouches or sachets—double-sided adhesive tape offers advantages that go far beyond adhesion.

(1) Clean and professional presentation

For premium brands, the visual experience of unboxing matters as much as the product itself. Double-sided tape allows manufacturers to attach inner layers, zippers, or flaps without visible seams or excess tape, resulting in a cleaner, more refined look.

(2) Enhanced functionality

In resealable coffee or snack packaging, double-sided adhesive tape helps secure inner valves or reclosable seals, maintaining freshness and prolonging shelf life. It’s particularly useful for products sensitive to air and moisture, such as coffee beans, tea leaves, or dried fruits.

(3) Lightweight and efficient

Compared to liquid adhesives or mechanical fasteners, double-sided tape is lightweight and easy to apply, making it ideal for automated packaging lines. It reduces material waste and simplifies manufacturing, contributing to greater production efficiency.

(4) Versatile bonding performance

Depending on the carrier material and adhesive type, double-sided adhesive tape can bond paper, plastic, metal, or fabric surfaces. This versatility allows brands to use it across multiple packaging formats—from outer boxes to flexible laminates.

Why Regular Tape Still Matters?

While double-sided adhesive tape plays an important role in packaging assembly, regular tape remains irreplaceable in sealing and shipping applications.

It offers:

l Strong external protection against dust, humidity, and tampering.

l Ease of use, especially for logistics and e-commerce businesses handling large shipment volumes.

l Brand visibility, as custom-printed tapes can serve as part of a brand’s visual identity.

For example, when packaging roasted coffee for shipment, MTPAK often combines custom-printed kraft paper tape with branded corrugated boxes, ensuring the parcel is both secure and visually aligned with the brand story.

Choosing the Right Tape for Your Packaging Needs

The choice between double-sided adhesive tape and regular tape depends on your packaging goals.

Ask yourself:

l Do you need a hidden bonding solution that enhances presentation?——Choose double-sided tape.

l Are you sealing cartons for transport or storage?——Use regular packaging tape.

l Do you want an eco-friendly option?——Consider paper-based tapes with natural rubber adhesives.

At MTPAK Packaging, we help brands integrate the right adhesive solutions into their packaging systems. Whether you’re building resealable coffee pouches, custom-printed boxes, or subscription packaging kits, our team can recommend the best tape types to optimize both performance and sustainability.

Conclusion

In packaging, even the smallest details—like the type of tape you use—can shape your brand’s overall impression. Double-sided adhesive tape and regular tape may seem similar, but each serves a unique purpose: one focuses on precision and design, the other on strength and protection.

By combining both effectively, brands can achieve secure, visually appealing, and cost-efficient packaging that enhances the customer experience from the moment the product arrives.

Want to know more about flexible packaging solutions? Welcome to contact MTPAK:

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak