What Kind of Material Is Polyethylene and Why Used it in Packaging?

Polyethylene is the most widely used plastic packaging material, with widespread applications in both industry and daily life. First discovered by accident in the 1890s, polyethylene has since found widespread use in packaging, construction, electronics, healthcare, and other fields.

Today, polyethylene is favored for its high stability, short processing steps, food contact compatibility, and low price. These characteristics make it valuable in many other areas, including food and fast-moving consumer goods.

In the food and beverage industry, brands often need to consider product shelf life, packaging sustainability, and regulatory compliance when selecting packaging. While traditional flexible packaging substrates (PP/PA/PET) offer excellent barrier properties, they present challenges in terms of flexibility, lightweighting, and recyclability. As a global flexible packaging supplier and printing services company, MTPak has provided high-quality packaging solutions to hundreds of bakeries and DTC brands, helping them balance freshness, sustainability, and cost.

What is polyethylene?

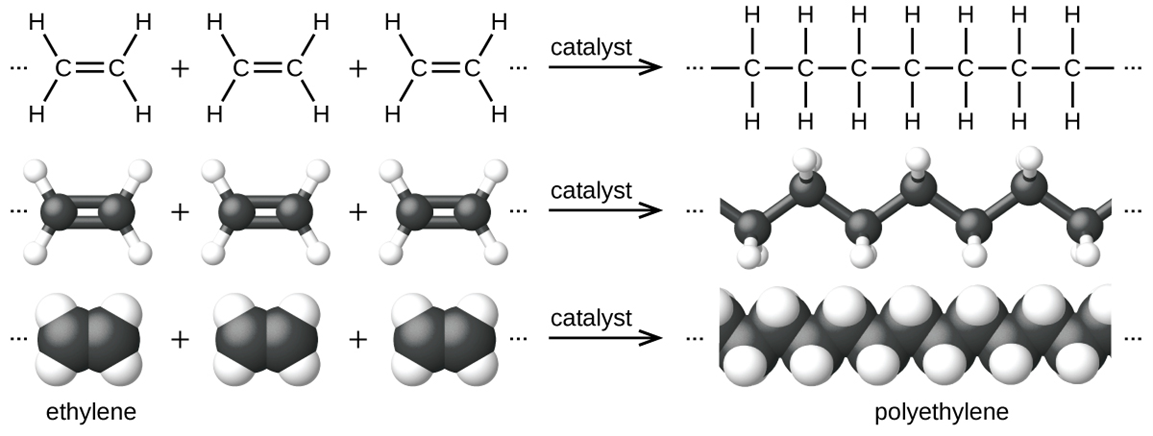

Polyethylene is a thermoplastic resin made by polymerizing ethylene. Its raw materials primarily come from petrochemicals. Its molecular structure is similar to paraffin wax, exhibiting long linear or branched chains, making it a typical crystalline polymer. It is tasteless, odorless, non-toxic, matte, and resistant to most acids and bases. It is insoluble in common solvents at room temperature, has low water absorption, and offers excellent electrical insulation.

Is polyethylene safe for flexible packaging?

Polyethylene is a commonly used heat-sealing material in flexible plastic packaging. It's low-cost and flexible, and is used in products like coffee bags and food packaging. For most flexible packaging products, the current mainstream approach is to use composite materials—combining multiple flexible packaging substrates to create an ideal, higher-performance material that meets the requirements of various products.

Polyethylene itself is non-toxic, and its raw material, ethylene monomer, is non-toxic. Even if polyethylene contains 200-300 ppm of ethylene monomer, it remains a non-toxic polymer and can be used in packaging that comes in direct contact with a variety of foods and pharmaceuticals. Although polyethylene was once classified as a Class III carcinogen, the safety of modern plastic products has been rigorously tested and is completely safe for everyday use, with no need for concern.

What are the types of polyethylene?

There are many types of polyethylene, classified by density and structure. Different PE grades have different properties, allowing consumers to choose the appropriate type based on their packaging needs.

Among them, low-density polyethylene (LDPE) is lightweight and flexible, with a wide range of uses. It is currently the most popular raw material for plastic bags. It has high impact strength at low temperatures and excellent resistance to alcohols, dilute alkalis and acids. It is generally used in shrink packaging, films, squeezable bottles, garbage bags, etc.

High-density polyethylene (HDPE) has higher mechanical strength and tensile strength than low-density polyethylene (LDPE), and is the preferred solution in the packaging and construction fields. From bottles to pipes, high-density polyethylene (HDPE) is an indispensable part of modern manufacturing.

Linear low-density polyethylene (LLDPE) has a higher melt temperature and melt viscosity than LDPE. When used as a heat-sealing material, it offers advantages such as resistance to contamination and the ability to achieve high heat-seal strength at low temperatures. Furthermore, its high melt viscosity makes it insensitive to temperature and processing stress, and it is often processed by mixing it with LDPE on standard equipment.

In addition, it can also be classified according to density into ultra-low density polyethylene (VLDPE), and according to molecular weight into ultra-high molecular weight polyethylene (UHMWPE) and high molecular weight high density polyethylene (HMWHDPE).

What are some common misconceptions when choosing polyethylene flexible packaging?

1. Confusing "degradable" with "recyclable": Traditional polyethylene is not compostable and should be distinguished from degradable materials like PLA and PBAT.

2. Ignoring process compatibility: Heat-sealing curves and film thicknesses vary significantly between different bag types. Failure to verify this beforehand can lead to increased leak rates.

3. Failing to verify regulatory compliance: BRC packaging certification, CNAS, FDA, and other certifications must be checked.

4. Not all PE bags are recyclable: While single-material structures can be recycled, some PVC and composite plastics are costly to recycle and are generally not recyclable, ending up in landfills or incineration.

Conclusion

Polyethylene materials have matured as packaging solutions, but when it comes to specific implementation, choosing the most suitable product for your application requires careful consideration of your company's qualifications, regulations, and actual processes. As a global flexible packaging partner, MTPAK has provided customized packaging solutions to companies across a variety of industries, including food and beverage, pet food, coffee and tea, household goods, personal care products, and pharmaceuticals. If you are considering replacing traditional packaging, please contact us for free samples.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak