What is Foil Packaging? The Ultimate Guide to Types, Benefits, and Applications

Packaging is a very important barrier in today's industry. It has to keep air, light, and moisture away from the product, which are all things that swiftly ruin its quality. Standard packaging often doesn't work for things like coffee, medicine, and delicate foods. This is where foil packaging proves its worth. At MTPak, we supply robust, high-barrier foil packaging solutions built for these exact challenges, serving global brands in food, beverage, and healthcare.

This article explains what foil packaging is, its key types, practical benefits, and how to select the right option for your product.

What is Foil Packaging?

Think of foil packaging as a protective shield made primarily from thin, rolled aluminum. Its core job is to block external elements—light, oxygen, moisture, bacteria—from compromising the product inside. You see it everywhere: the inner liner of your coffee bag, the wrapper on a chocolate bar, or the blister pack for pills.

The upside is its near-total barrier protection, which is essential for perishable goods. The downside? Pure foil can be prone to pinholing if too thin and requires lamination for sealability. Historically, foil moved from wrapping cigarettes in the early 1900s to becoming a food industry standard by mid-century. Today, it’s often laminated with plastics or paper to enhance functionality.

What Types of Foil Packaging Are Common?

Different products demand different foil formats. Picking the right one comes down to what you need to pack and how.

Aluminum Foil Rolls and Sheets

These are workhorses in kitchens and factories. They wrap food, cover trays, and assist in cooking. The upside is excellent heat resistance and moldability. The downside is that they lack structural support on their own.

Foil Pouches and Bags

This is where foil shines. Stand-up pouches with foil layers are common for coffee, snacks, and pet food. MTPak often integrates a foil barrier layer here. The upside is superior protection, lightweight, and resealability. The downside is that multi-layer structures can complicate recycling.

Blister Foil Packaging

The standard for pills and capsules. A thermoformed plastic cavity is sealed with a lidded foil. The upside is excellent product isolation, tamper evidence, and dose control. The downside is higher cost per unit compared to bottles.

Foil Wrappers

Used for high-end chocolates, pharmaceuticals, and steriles. The upside is full-wrap barrier protection and a premium look. The downside is limited structural protection for fragile items.

What Are the Advantages of Foil Packaging?

Here's what foil packaging actually does on the ground. It solves three basic problems: keeping oxygen out, blocking moisture, and stopping light degradation. Let's break it down with real examples.

Superior Barrier Properties

This is the main event. Foil provides an almost total barrier against oxygen, moisture, and light. Its water vapor transmission rate (WVTR) and oxygen transmission rate (OTR) are exceptionally low. The upside is dramatically extended shelf life. The downside is that if the foil layer is compromised, the barrier fails.

Lightweight and Strong

Aluminum foil is incredibly thin yet strong. The upside is reduced shipping weight and cost compared to rigid containers. The downside is that it can be punctured if mishandled.

Customizable and Printable

Foil laminates provide a smooth, bright surface for high-quality printing. The upside is strong shelf impact and brand messaging.

Where is Foil Packaging Commonly Used?

Foil packaging works where products need protection. Think about coffee beans losing their aroma, pet food going stale, or medicine losing its potency. These are real problems. Foil packaging steps in to block the main culprits: air and moisture. It's a straightforward solution for products that can't afford to degrade.

You see it in specific places:

Food & Beverage

Coffee bags (with a degassing valve), snack bars, ready meals, and dairy products. The upside is freshness preservation. The downside is that multi-material laminates are not always curbside recyclable.

Pharmaceuticals & Nutraceuticals

Blister packs for tablets, foil sachets for powders. Packaging must comply with FDA 21 CFR or EU 1935/2004 regulations. The upside is patient safety and compliance. The downside is higher material cost.

Cosmetics & Personal Care

Creams, serums, and lotions in foil sachets. The upside is protecting active ingredients from air and light. The downside is that small formats can feel less premium to some consumers.

Industrial Applications

Foil is used in insulation materials and as a moisture barrier in construction, or for shielding sensitive electronic components.

Foil vs. Other Packaging Materials: How Does It Stack Up?

Foil vs. Plastic

Standard plastic films have poor barrier properties. High-barrier plastics (e.g., with EVOH) can approach foil’s performance but are often more sensitive to moisture. The upside of foil is a more consistent and robust barrier. The upside of plastic is often simpler recyclability.

Foil vs. Paper

Paper is permeable. The upside of paper is a sustainable image and often better compostability. The downside is that it requires a foil or plastic laminate to achieve any meaningful barrier, which complicates end-of-life processing.

Choose foil when maximum product protection is non-negotiable.

What About Environmental Impact and Recycling?

This is the tricky part. Aluminum is 100% recyclable infinitely. The upside is that recycling it saves ~95% of the energy needed for new aluminum. The downside is that laminated packaging (e.g., foil with plastic) is difficult to recycle in most municipal systems. The materials must be separated, which isn't economically feasible at scale.

The industry is responding. MTPak offers options using recyclable polyolefin structures where possible and materials from certified sources (FSC/PEFC paper). The future lies in mono-material plastics that are recyclable but still offer high barriers, though they aren't quite at foil's level yet.

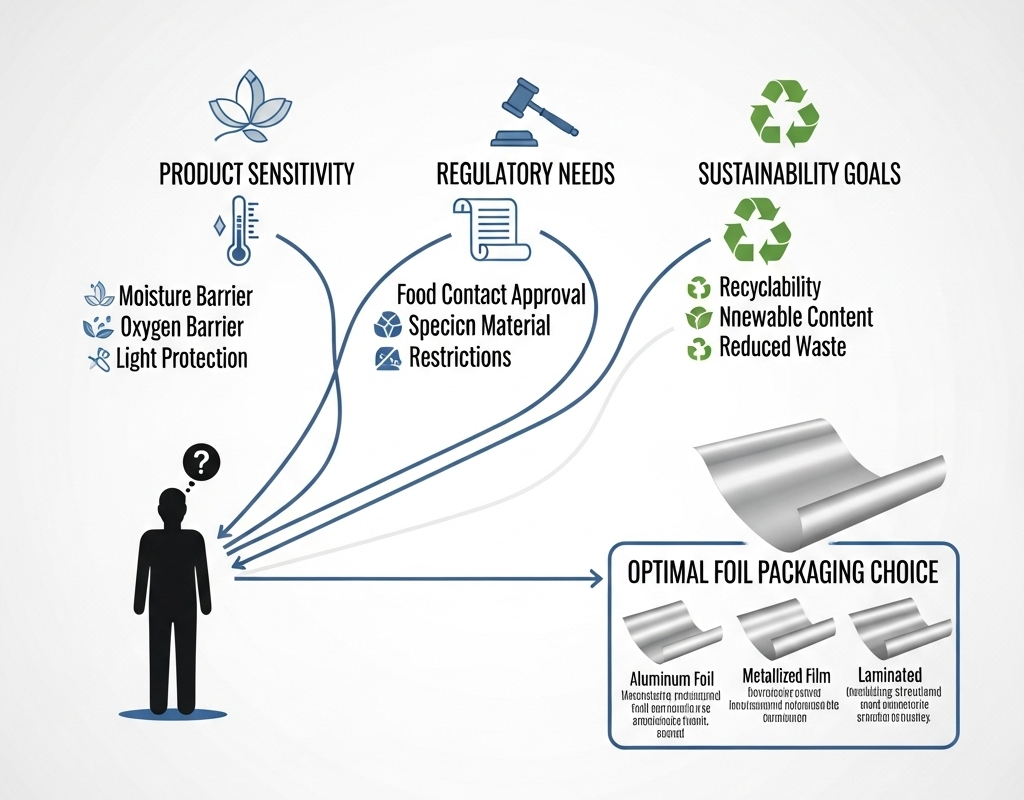

How to Choose the Right Foil Packaging

Think like an engineer. Match the package to the product.

1. Assess Product Sensitivity

How sensitive is your product to oxygen, moisture, and light? Coffee and spices need a high oxygen barrier. Dry snacks need a good moisture barrier. This determines the required foil thickness and laminate structure.

2. Define Regulatory Needs

Food, pet food, and medical products have strict rules. Ensure your supplier understands FDA and EU compliance and can provide the necessary documentation.

3. Consider Sustainability Goals

If recyclability is a priority, discuss options with your supplier. Mono-material plastic barriers might be sufficient. If not, foil is your best bet for protection, and you can explore options with certified papers.

4. Work with an Expert Supplier

This is critical. A supplier like MTPak doesn’t just sell bags. We provide material science expertise. We can guide you on the right structure, ensure thermal seals will hold on your filling line, and help you navigate the trade-offs between protection, cost, and sustainability.

Conclusion

Foil packaging remains the gold standard for product protection. It solves the fundamental problem of shelf life for oxygen and moisture-sensitive products.

At MTPak, we approach packaging with a technical mindset. Our value is in providing durable, reliable foil-based solutions that perform on the production line and in the market. We help you select the right materials, ensure compliance, and avoid costly over-engineering.

Contact our team to discuss your product’s needs and get a quote.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak

Frequently Asked Questions (FAQ)

1. What is foil packaging used for?

It protects products that spoil easily. Coffee bags use foil to block oxygen. Pharmaceutical blister packs rely on foil seals to keep pills dry. Pet food bags need it to prevent fats from turning rancid.

2. Is foil packaging better than plastic?

Depends on the job. Foil wins on barrier protection — it completely blocks oxygen and light. Plastic often costs less and weighs less. For long-term protection, foil is the better choice.

3. What are the disadvantages of foil packaging?

The main issue is recycling complexity. Laminated foil pouches can't be processed in standard recycling systems. Foil also costs more than basic plastic films. It can tear if handled roughly.