What is a Lifecycle Analysis (LCA) and How Does it Guide Sustainable Packaging Decisions?

People talk a lot about packaging that lasts. But it's not always easy to make a better choice. Is paper better than plastic? What about things that can be composted? The answers are not often easy. A Lifecycle Analysis, or LCA, is what you need. It uses data to look at everything, from the raw ingredients to the trash. We employ LCA concepts at MTPak to assist brands in the coffee, pet food, and consumer goods industries to stop guessing. This strategy cuts through noise and gives unambiguous, scientific proof for decisions about packing.

This article talks about what an LCA is, how it works in real life, and why it's important for making sensible, long-lasting choices about packaging.

Why Can't We Rely on Intuition for Sustainable Packaging?

Common assumptions often lead us astray. A paper bag might seem like the obvious eco-choice, but its production can be water and energy-intensive. A lightweight plastic pouch might have a lower carbon footprint during transport. Without hard data, companies risk "greenwashing" or, worse, choosing packaging that has unintended environmental consequences. For a coffee bag or a pet food pouch that sells millions of units, even a small oversight gets magnified. An LCA replaces gut feelings with facts.

What Exactly is Lifecycle Analysis (LCA)?

Think of an LCA as a full environmental audit for a product. It's a standardized method (like ISO 14040/14044) that quantifies the environmental impact of packaging at every stage of its life. It doesn't just measure carbon emissions. It looks at water use, fossil fuel consumption, mineral resource use, and even ecotoxicity. For a packaging supplier, this means tracking the journey from the ground to the garbage bin and everywhere in between. The goal is to get the complete story, not just a chapter.

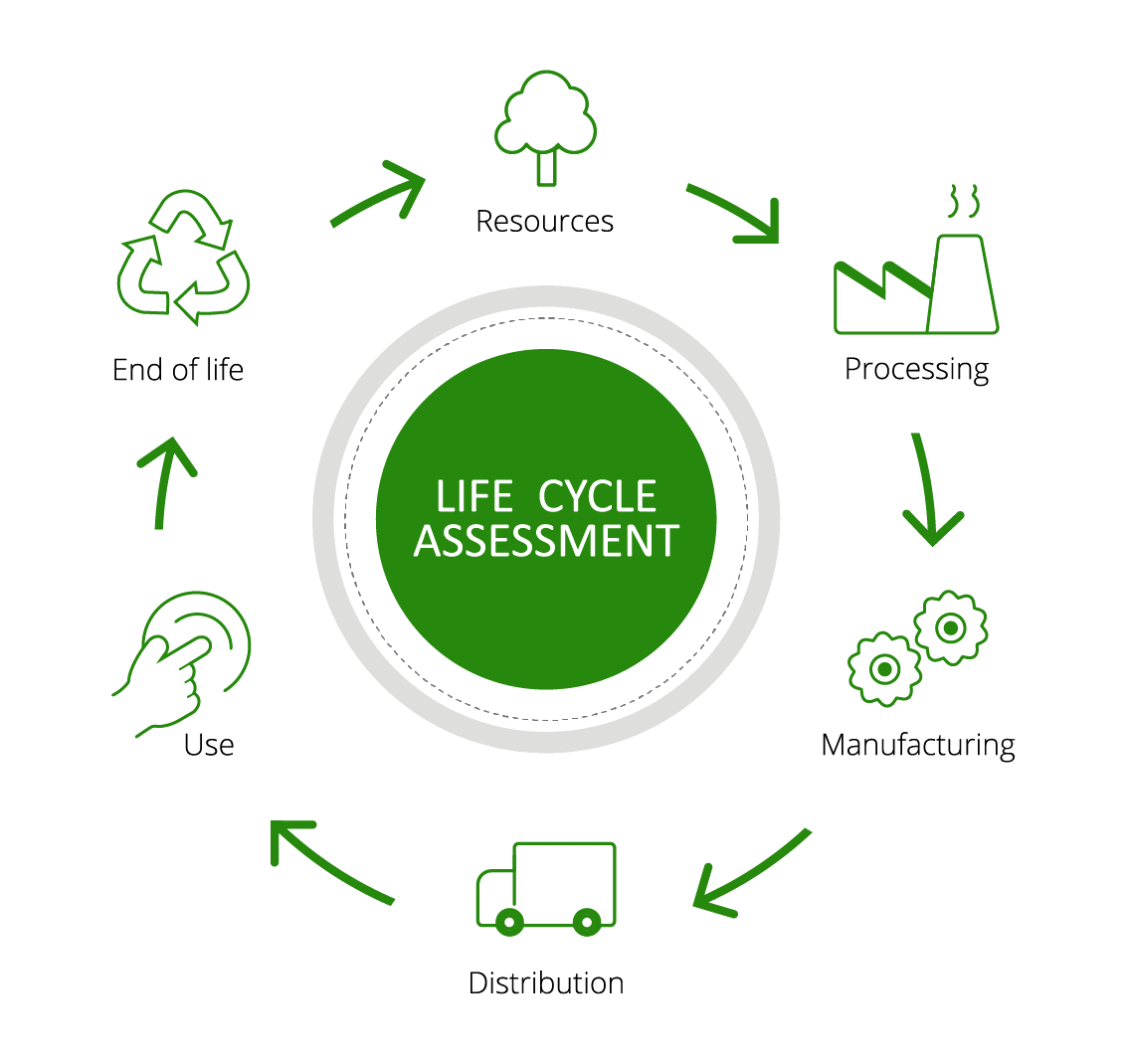

What are the Key Stages in a Packaging LCA?

An LCA breaks down the packaging lifecycle into distinct, measurable phases. This structure ensures nothing is missed.

1. Raw Material Extraction

This is where it all begins. It looks at how getting materials affects things, such as drilling for oil to manufacture plastic, cutting down trees to make paper, or cultivating maize to make PLA. The assessment takes into account how land is used, how much water is used, and how much energy is needed for the first processing.

2. Packaging Manufacturing

This is where raw materials get turned into your final packaging. This step figures out how much energy, water, and chemicals are consumed in factories. It also takes into account the waste that is made. At MTPak, we focus on making things quickly to keep the impact low at this point.

3. Transportation and Distribution

It is important for packaging to get to where it is required. This phase evaluates the environmental cost of logistics—shipping materials to converters, finished pouches to fillers, and boxed products to retailers. Distance, transport mode (ship, plane, truck), and packaging weight are critical factors. Compared to a glass jar, a lightweight coffee bag can cut down on shipping emissions by a lot.

4. Usage Phase

How does the packaging perform in the real world? Does a high-barrier layer (like EVOH) prevent food spoilage and waste? Is the design user-friendly, or does it lead to product waste? This step links the design of packaging to how people act.

5. End-of-Life

This is the last footprint. Where does the packaging go when it is used — to a landfill, an incinerator, or a recycling center? The LCA looks at how each manner of disposal affects the environment. The result of this step depends on how successfully the coffee pouch or pet food bag can be recycled or composted at a factory.

How Do You Actually Use an LCA to Make Decisions?

An LCA isn't just a report; it's a decision-making tool. Here’s how it guides practical choices.

Strategic Material Sourcing

LCA data reveals the true cost of materials. It allows you to compare the Global Warming Potential (GWP) of virgin plastic against post-consumer recycled (PCR) content or compostable polymers. The results often surprise. For instance, using PCR materials can dramatically lower the carbon footprint of a plastic bottle or pouch. This data helps you source smarter.

Optimizing Design and Logistics

The LCA might show that transportation is your biggest carbon hotspot. The solution? Redesign for efficiency. Switch to a lighter material. Design a flat-bottom coffee bag that ships more compactly. Reduce unnecessary layers in a pet food bag. Even a small weight reduction adds up fast across a global supply chain. It’s a direct way to cut costs and emissions.

Planning for End-of-Life

The LCA clearly shows the environmental benefit of recycling over landfilling. This knowledge should directly inform design. Choose mono-materials over complex laminates that are hard to recycle. If opting for compostable packaging for your coffee brand, ensure the infrastructure exists for customers to compost it correctly. The goal is to design packaging with a planned second life.

How Does an LCA Help with Compliance and Brand Trust?

Beyond internal optimization, an LCA is crucial for navigating the external landscape.

Meeting Regulatory Hurdles

Regulations like the EU's PPWR and plastic taxes are becoming more common. An LCA gives you the verifiable information you need to show that you are following the rules. You can use it as proof that a package has recycled content or can be recycled. If you don't have it, you're at risk.

Building Credible Marketing Stories

Consumers don't believe statements about becoming green. An LCA gives you a solid base to work from. You can convey things like, "This pharmacy bottle uses 30% less energy to make based on our LCA," instead of making imprecise generalizations. Such openness can generate true trust and set your business apart in the congested market.

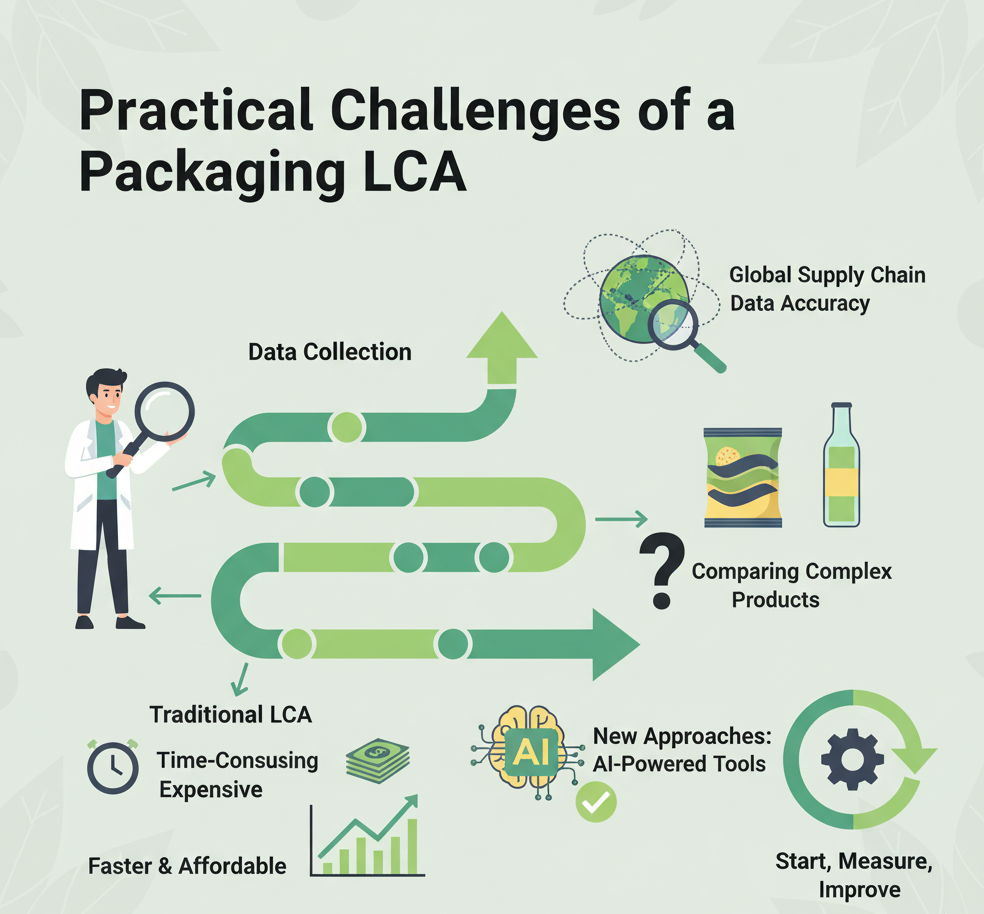

What are the Practical Challenges of an LCA?

LCAs aren't perfect. Traditional methods are time-consuming and expensive. Getting accurate data from a global supply chain is tough. Comparing a complex laminate snack bag to a simple glass bottle is complicated. But new approaches are changing this. AI-powered tools can now model scenarios faster and at a lower cost, making LCA insights accessible even for smaller companies. The key is to start with the best data you have and iterate.

Conclusion

A Lifecycle Analysis makes sustainability more than just a buzzword; it gives it a blueprint. It provides you with the solid proof you need to make packaging choices that are truly better for business and the environment.

At MTPak, our approach is grounded in this reality. We use FSC-certified paper, home-compostable films (ASTM D6400), and PCR materials to make packaging. More significantly, we help you use LCA thinking to choose the best choice for your product by balancing barrier needs (OTR/WVTR), shelf appeal, and the realities of the product's end of life. We specialize in long-lasting, useful answers for coffee, pet food, and dry goods.

Are you ready to make packaging choices based on data? Get in touch with MTPak to talk about what you need.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak

Frequently Asked Questions (FAQs)

1. What's the real difference between an LCA and a carbon footprint?

A carbon footprint is just one number: total CO2 equivalent emissions. An LCA is a full assessment that includes carbon footprint plus other impacts like water use, land use, and toxicity. It gives you a complete environmental profile.

2. Which LCA stage matters most for packaging?

It depends entirely on the package. For a heavy glass bottle, transportation might be the hotspot. For a complex plastic pouch, raw material production could dominate. The LCA's value is pinpointing your specific hotspot.

3. How does using recycled content affect the LCA results?

It significantly lowers the impact in the raw material extraction phase. The LCA credits the package for avoiding the need to produce virgin material. This is why using PCR plastic often shows a major carbon reduction.