What Are The Common Types of Poly Bags and Which Material Is The Best?

Welcome back! Poly bags are almost the most common form of packaging. From supermarket shopping bags to takeout bags and food storage bags, poly bags have become an indispensable packaging carrier in daily life and commercial scenarios.

But for brands, the question is often not whether to use plastic, but rather which material is best for their product. Faced with a wide variety of poly bags, many people are unaware of the differences in material, making it even more difficult to determine which material best suits their needs.

As a solutions provider with many years of experience in the flexible packaging industry, MTPAK boasts a professional R&D team and extensive practical experience. It can provide innovative, customized services tailored to the specific needs of brand clients and buyers. To date, it has helped hundreds of customers solve various packaging challenges.

In reality, the core difference between poly bags lies in their base material. Different materials offer vastly different heat resistance, safety, and functionality. Choosing the right material is crucial for achieving a balance between practicality, safety, and cost. Here's a quick reference guide to various poly bag types. Let's read on!

What are the common types of plastic bags?

The mainstream poly bags on the market can be divided into several different products according to bag type, function, and usage scenarios. Each type of material has its own unique performance and adaptation scenarios, covering almost all daily and commercial needs.

Classification by bag structure

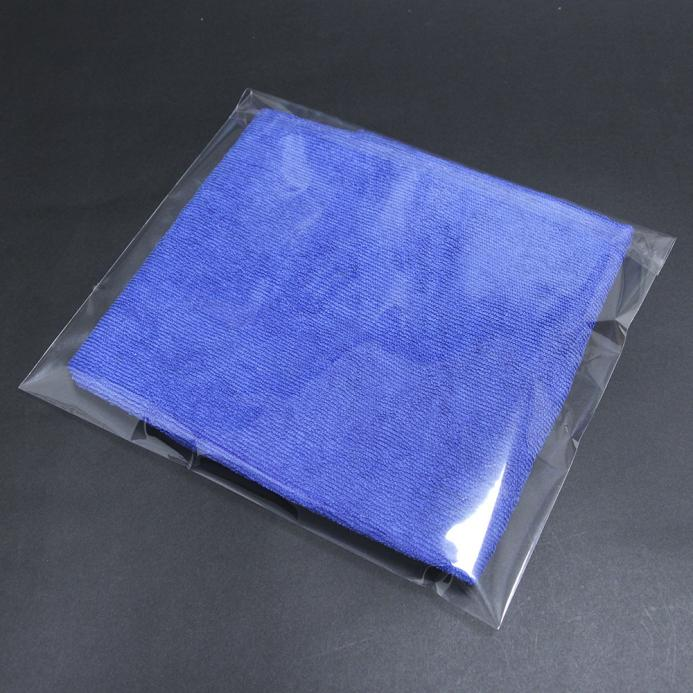

1. Flat Bags: This is a simple-structured and most common poly bag. It is usually sealed on three sides and open on one side. It can only hold thin items and is suitable for food inner packaging, clothing packaging, and parts packaging.

2. Gusseted Bags: Also known as accordion bags, these feature gussets on the sides or bottom. The top can be sealed with a heat seal, zipper, or drawstring. Some also feature gusseted bottoms to further increase load-bearing capacity and create a three-dimensional effect. When unfolded, these gusseted bags can easily accommodate tall and bulky items like nuts, coffee beans, and toiletries, while maintaining a firm, rigid shape.

3. Roll Bags: These are poly bags processed through a continuous process to create seamless tubular or flat rolls with perforation. To use, individual bags are torn from the roll and then sealed as needed.

Simply put, roll bags are a package of multiple bags on a continuous roll. For example, a roll of fresh produce bags sold in supermarkets may contain 50-100 bags. These bags can be torn off and used to store vegetables or meat, making them convenient for bulk use while reducing the storage space required for individual bags.

4. Poly Tubing: Polyethylene tube bag is a continuous, unsealed tubular film with no reserved dividing lines for cutting. Unlike roll bags, it is not made up of multiple independent bags connected together. When used, it needs to be cut with professional cutting tools according to the length of the item and then sealed at both ends. The advantage is that the size can be flexibly adjusted according to needs and is also suitable for some automated packaging production lines.

Classification by functional characteristics

1. Resealable Bags: These are poly bags with a reclosable seal (such as a zipper, snaps, or self-adhesive tape) installed on the bag's opening. Once opened, the bag can be quickly resealed and reused without the need for additional tools (such as clips or string). These bags are particularly suitable for the elderly, children, or for outdoor use (e.g., sealing snacks at picnics). They are currently commonly used in food storage, daily chemicals, cosmetics, facial masks, and pet food.

2. Write-on Bags: These are poly bags with a white, writable area on the bag, allowing users to write important information such as the date and contents with a standard pen. Some white, marked bags are also resealable. They have a wide range of applications, including labeling sample bags in laboratories to ensure accurate identification and traceability. They can also be used to record information about medicines and food in household storage. Furthermore, labeling can be used in industrial production, retail, and other scenarios to facilitate item classification and rapid identification.

3. Anti-static Bags: These functional bags are designed specifically to protect static-sensitive items (such as electronic components and precision parts). Their core function is to eliminate or control static electricity accumulation, preventing damage to items caused by electrostatic discharge (ESD). The poly bag's base material is coated with an antistatic agent, which forms an extremely thin conductive film on the bag's surface, quickly conducting static electricity generated by friction to the outside. These bags are typically made of polyethylene terephthalate (PET) and are commonly used in electronics manufacturing, the military industry, aerospace, and other specialized fields.

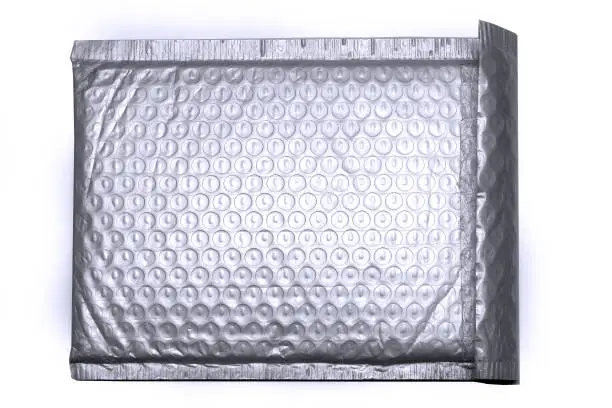

4. Bubble Bags: This type of functional packaging utilizes air cushioning as its core. The air bubbles within the bag absorb impact energy, protecting fragile, delicate, or delicate items during transportation and storage. Essentially, they are made from two layers of plastic film, typically made from PE. In some cases, PP or composite anti-static or puncture-resistant films are used. These provide cushioning while also meeting additional requirements such as anti-static and scratch resistance.

Classification by Usage Scenarios

1. Mattress & Furniture Bags: These two products are customized protective packaging designed for large, fragile household items, protecting them from contamination, wear, and moisture during transport and storage. As the name suggests, mattress bags are large poly bags designed specifically for mattresses. They are typically made of thickened HDPE or LLDPE. Most mattress bags feature an open design and are sealed with a cord or tape. Some high-end models include zippers for a complete seal when placed over a mattress. Furniture bags are designed for sofas, chairs, wardrobes, coffee tables, and other furniture. They are sized for a flexible fit and are typically made of LLDPE or woven PE composite film.

2. Trash Liners/Pallet Covers: Trash bags are poly bags used to hold household, commercial, or industrial waste. They're primarily made of HDPE or LLDPE. Based on the characteristics of different waste types, they're also designed with features like oil resistance, puncture resistance, and biodegradability. Pallet covers, on the other hand, are large plastic covers designed specifically for palletized cargo. They're commonly used in e-commerce warehouses, manufacturing plants, and cross-border logistics. Their dimensions strictly match standard pallets (such as the 1200mm x 1000mm international standard pallet), and they're primarily made of thickened HDPE, with some high-end models using LLDPE.

3. Mailing Bags: These are designed for packaging letters, documents, and small items. Unlike ordinary poly bags, they also meet the logistics needs of express delivery, long-distance transportation, and information labeling. Polyethylene is the primary material, but some high-end mailing bags use composite materials and offer additional puncture resistance or light shielding. While lightweight is paramount, most mailing bags feature self-adhesive closures, which improve e-commerce delivery efficiency. Some document mailing bags use flap closures similar to traditional envelopes and are recyclable through plastic recycling systems.

For consumers, which plastic bag material is the best?

Many people debate which material is best. In reality, there's no single answer to this question. The key to determining a material's quality lies in its compatibility with the intended use, product characteristics, and safety and compliance requirements. For example, for hot soup bags, PP is definitely better than PE; however, for frozen meat, PE is more suitable than PP.

Therefore, there's no single best material, only the material that best suits the product.

Conclusion

Poly bags come in a variety of shapes, functions, and materials, each suited to specific applications. Brands need to consider product characteristics, consumer experience, regulatory compliance, and sustainability when choosing packaging.

MTPAK, with its professional, high-quality production equipment and technical team, offers customized solutions ranging from flat bags and gusseted bags to functional flexible packaging, helping brands strike a balance between cost, performance, and environmental performance.

For more information about MTPAK products, please call or contact our sales team.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak