The Complete Barrier Packaging Guide: Keep Coffee & Food Fresh

Getting products from production line to customer involves real risks. Moisture, oxygen, and light can degrade freshness, flavor, and potency. For items like roasted coffee, pet food, or snacks, packaging is a functional necessity—it directly determines shelf life and product integrity. At MTPak, we supply flexible packaging that addresses this. Our barrier solutions are made to safeguard your goods so that they arrive in the same condition as when they left.

This guide tells you what barrier packaging is. We talk about how it works and how to choose the correct amount of protection for your needs.

What is Barrier Packaging?

Barrier packing is any material that stops the flow of gases, moisture, or smells — think of it as a firewall. Its job is to keep things that shouldn't be there from getting in and things that should be there from going out.

This barrier creates a modified atmosphere inside the package. It directly prevents oxygen from spoiling fats and oils, stops moisture from making crackers soft or dry goods clumpy, and protects against UV light degrading colors and nutrients. For products like coffee or pet food, it also acts as an aroma barrier, locking in the fresh scent. MTPak's solutions are built on this principle of creating a dedicated protective environment for your product.

How is Barrier Performance Measured?

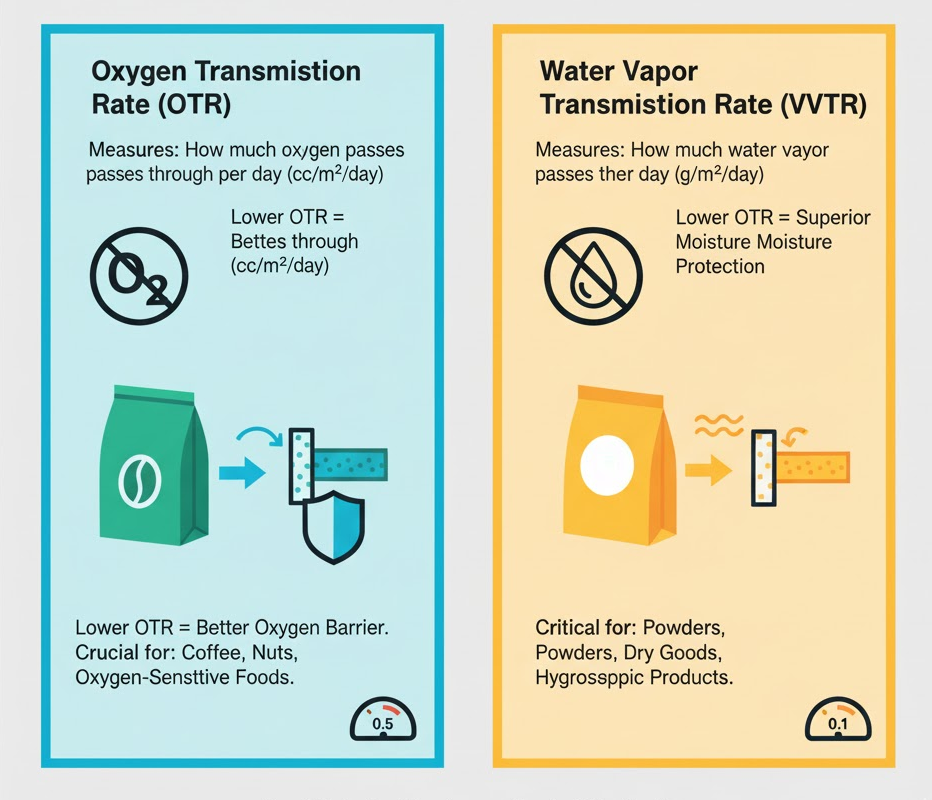

The two most important metrics for the industry are the Oxygen Transmission Rate (OTR) and the Water Vapor Transmission Rate (WVTR). They tell us for sure how a material will work.

Oxygen Transmission Rate (OTR)

OTR measures how much oxygen goes through a square meter of material in a day. We report it in cc/m²/day. A lower number suggests that the oxygen barrier is better. For a coffee bag, a low OTR is a must to keep it from going stale.

Water Vapor Transmission Rate (WVTR)

WVTR measures how much water vapor permeates the material in 24 hours, usually in g/m²/day. Again, a lower value means better protection against moisture. This is very important for keeping powdered drink mixes and dry baking goods from clumping together.

These tests follow ASTM or ISO standards. If this sounds technical, that's because it is. Our team at MTPak interprets these numbers daily to match materials to product needs, ensuring you get the protection you're paying for.

Why Do Products Need Barriers?

The short answer: to maintain quality and reduce waste. A proper barrier is your first and best defense against the environment. It’s a game-changer for product consistency.

First, it preserves freshness. By blocking oxygen, it slows down oxidation and rancidity; by controlling moisture, it maintains texture — this directly translates to a longer shelf life. Second, it ensures safe travel. A robust barrier pouch can handle supply chain stresses without compromising the product inside. Finally, flexible films are lightweight and cost-effective compared to glass or metal. The key is that plastics are naturally permeable; the barrier layer is what makes them functional for demanding applications.

What Are the Different Barrier Protection Levels?

Barrier protection isn't one-size-fits-all. It's a spectrum, from basic to fortress-like. We typically categorize films into four distinct levels, each with a specific job.

Basic Barrier - Single Layer

This is your starting point. A single layer of PP or PE offers minimal protection against light, oxygen, and moisture. It works for short-term, non-perishable items or as an overwrap. Think of a basic bread bag. It won't significantly extend shelf life.

Basic Barrier - Multilayer

Here, we laminate two materials, like PET and PE. The PET adds gas and aroma resistance, while the PE provides moisture protection and heat-sealability. It's a step up for products like nuts or grains that need better defense than a single layer can offer.

Moderate Barrier

This is where we see a real jump in performance. Using coatings or metallization, like in our PET/VMPET/PE structures, significantly improves the oxygen barrier. These materials effectively block gas, moisture, and aromas. They are a solid choice for many pet treats, snacks, and coffee blends.

High Performing Barrier

You need a high barrier for the hardest jobs. These types have multilayer structures, and they often incorporate a thin layer of aluminum foil (AL) or sophisticated coatings on them. They make it almost impossible for oxygen, moisture, light, and smells to get through. It is the level you need to package luxury coffee, oily pet food, or sensitive drugs.

How Do Customers Choose the Right Barrier Level?

Selecting a barrier is a practical decision. You balance product needs with cost. The goal is adequate protection without over-engineering. Ask a few simple questions.

What is your product's main enemy? Is it oxygen (like for coffee oils), moisture (for powder), or both? What is your target shelf life? A 3-month shelf life has different requirements than a 12-month one. Consider your storage environment. A climate-controlled warehouse is easier on packaging than a volatile one. For instance, a basic barrier might suffice for short-shelf-life baked goods, while freeze-dried camping meals need a high barrier. MTPak helps you run through these questions to find the most cost-effective solution for your specific situation.

How Do Barriers Work with Sustainable Packaging Goals?

Many people think that high barrier indicates that something can't be recycled — that isn't the case now. The industry has come a long way in producing high-barrier choices that are better for the environment.

MTPak offers solutions like monomaterial polyethylene (PE) laminates that can be recycled. We also employ plant-based polymers like PLA (polylactic acid) that have specific aluminum oxide (ALOX) coatings on them. This ALOX covering keeps out a lot of oxygen and moisture and lets the bag be composted in an industrial setting. It's a good choice for firms that want to safeguard their products while also lowering their impact on the environment.

Conclusion

Choosing barrier packaging is a technical but very important component of making a Understanding OTR, WVTR, and the different protection levels allows you to make an informed decision that safeguards your product and your brand.

At MTPak, we believe that working together is the best way to make better packaging; thus our team is like an extension of yours. We work together to come up with solutions that address problems before they happen, from filling line compatibility to global logistical stress. When you choose MTPak, you get more than just a provider; you get a partner who wants to help you cut down on waste and improve your brand's value.

Contact MTPak today to talk to our packaging experts about what you need for your project.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak

Frequently Asked Questions (FAQ)

1. Does coffee packaging always need to have a high barrier?

Yes, a high barrier is strongly suggested for whole beans or ground coffee. The oils and smells in coffee are quite volatile and can easily oxidize. The easiest approach to keep food fresh and tasty is to put it in a bag with a low OTR and a high barrier.

2. How can I tell whether my packing material meets FDA standards?

All materials used in food-contact packaging must be FDA compliant. At MTPak, we make sure that all of the materials we sell for food items exceed the FDA's guidelines. You might ask for a compliance statement to keep for your records.

3. Is it possible for me to get a transparent package with a high wall?

Absolutely. While aluminum foil is opaque, metallized films (like VMPET) offer a high barrier and are semi-transparent. For a fully clear high barrier, transparent oxide coatings (like ALOX on PLA) are an excellent option, though the barrier level may be slightly lower than foil.