The Basics of Retort Pouch Packaging: What You Need to Know

People have kept food in glass jars and cans for a long time, but they are heavy, hard to handle, and not as useful in today's busy markets. The packaging for retort bags is sturdy and light, and it keeps food safe for months without needing to be refrigerated.

MTPak Packaging is a company that specializes in flexible packaging. They can assist you switch from old-fashioned cans to new-style trays and retort bags. MTPak makes high-barrier pouches that may be customized to keep food safe and look good on store shelves. This helps businesses save money, make things easier, and talk to customers more easily. In this article, you will learn what a retort pouch is, how it compares with traditional cans, which materials are used in its construction, how the processing works, and what equipment is required for large-scale production.

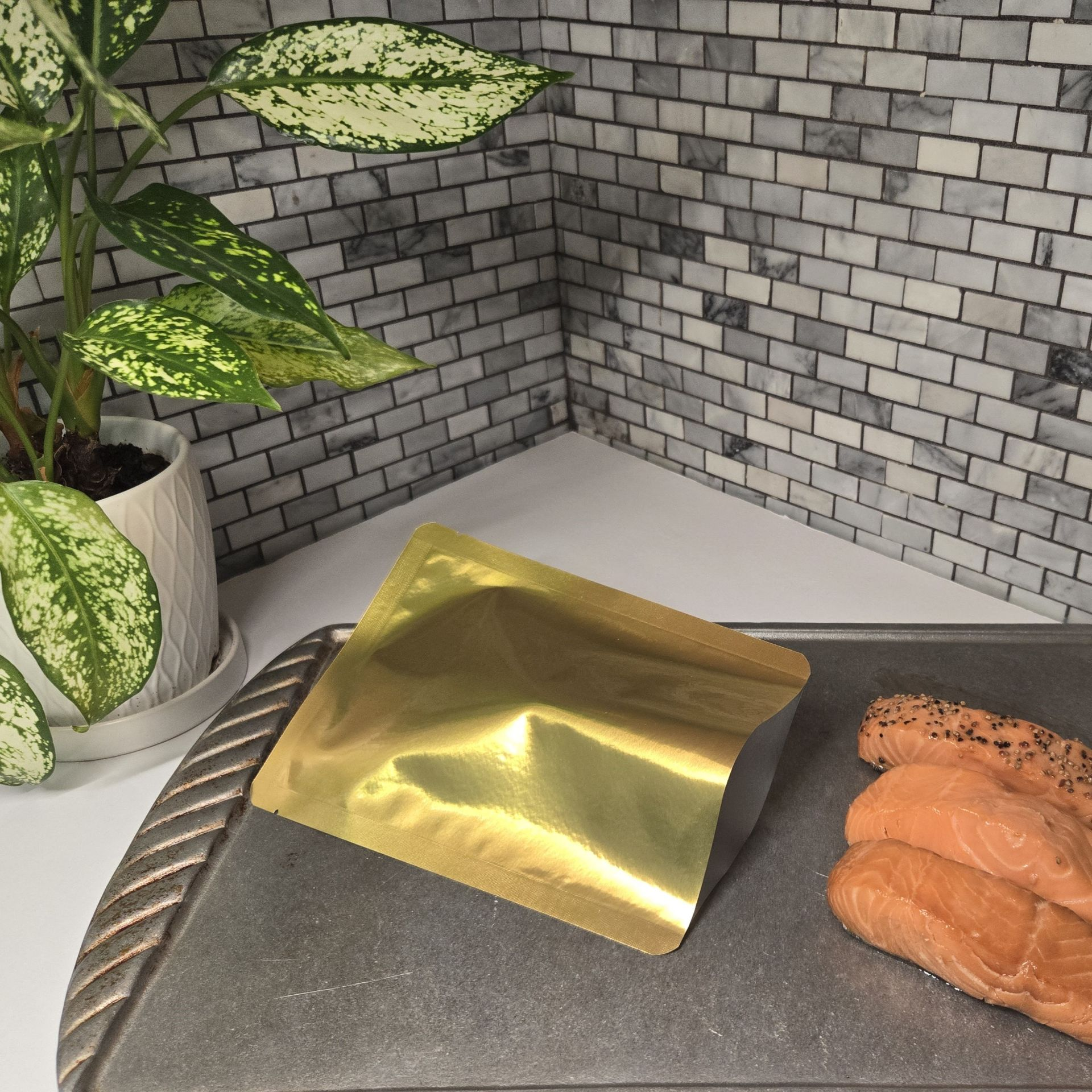

What Is a Retort Pouch?

A retort pouch, also known as a retort bag or retortable pouch, is a laminated, heat-resistant packaging that may be sterilized inside a pressurized vessel. Retort pouches are made up of many layers of films and barrier materials. They are as strong as cans but as easy to use as flexible packaging.

The pouch is filled with food and then sealed tightly. It is then put under a lot of heat and pressure. This method makes retort pouch food that is safe and stable at room temperature for 12 to 24 months. Manufacturers and consumers both like them since they are light, easy to carry, and have surfaces that can be printed on.

Retort Pouch vs Can: Which Is the Smarter Choice?

Both retort pouches and regular cans are meant to keep food safe by sterilizing it, but they do it in quite different ways. It's easier to figure out which format will work best if you look at the pros and cons of each one independently.

What Are Pros and Cons of Retort Pouches:

Because they are light and take up little space, retort pouches are becoming more and more popular for ready-to-eat meals and pet food. But, like every other type of packaging, they have their limits.

点击图片可查看完整电子表格

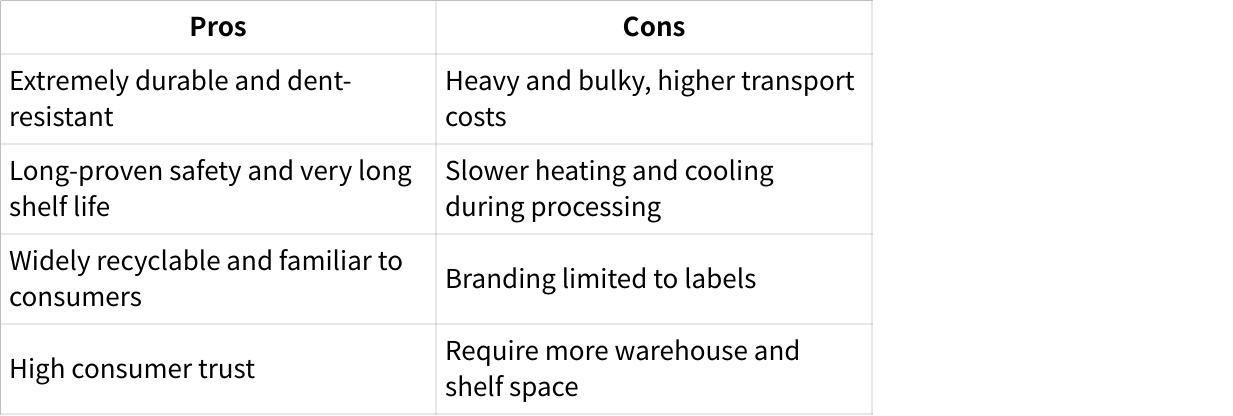

What Are Pros and Cons of Cans?

People still trust cans as one of the best ways to package things that don't need to be refrigerated. They like how strong and familiar they are. They nevertheless have drawbacks when it comes to weight and efficiency.

点击图片可查看完整电子表格

What Materials Are Used in Retortable Pouches?

They work because they have a lot of layers, and each layer does something different:

Polypropylene (PP):

It is the layer that touches the food the most on the inside. You can use heat to seal this layer. It protects the shape of the product and makes sure there is a strong seal that keeps air out. This makes it last longer.

Aluminum Foil:

This is the most critical layer that protects everything. Three things that make food taste bad and are bad for its safety are oxygen, water, and light. This layer is very important for keeping food fresh and making it last longer.

Polyester (PET):

The top layer is made of polyester, also called PET. PET is sturdy, can be written on, and doesn't melt when it's hot. It also protects the pouch while it is being handed out and used.

These layers work together to make retortable bags strong enough to be sterilized without losing the taste and nutrition of the food.

Businesses are also making more environmentally friendly decisions. One novel idea is to make laminates out of solely PP or only PE. These can be used again and over again. You don't have to use metal to make it simpler to find and get back. Instead, you can utilize clear high-barrier coatings. Three of the most critical elements that go into manufacturing a modern retort pouch are safety, durability, and being good for the environment.

How Does Retort Pouch Processing Work, From Filling to Sterilization?

The process of creating retort bags is always watched to make sure that the quality of the products and the safety of the food stay high. Most of the time, these steps are taken:

1. Filling

You can say that the bag has liquid, semi-solid, or solid food in it. Precision filling makes sure that all the bags are the same size and weight.

2. Air Removal

Inert gas cleaning or vacuum sealing could be employed to get rid of the extra air. This makes it easier for heat to move around when cleaning and stops oxidation.

3. Sealing

The pouch is entirely sealed when heat and pressure are applied. To keep things clean and free of germs, you need a seal that is airtight.

4. Sterilization in the Retort

In a retort chamber, sealed bags are put under a lot of pressure and very high temperatures, usually between 116 and 121 degrees Celsius. By getting rid of potentially harmful microbes, this approach makes perishable goods last longer.

5. Cooling

Cool the food down right away after cleaning it. This keeps the meal's texture, flavor, and nutritional value intact.

6. Inspection and Quality Control

Before we package a batch for storage or shipping, we examine its cleanliness, seal strength, and overall quality.

What Equipment Is Required for Retort Pouch Packaging?

Scaling production requires specialized equipment. A retort pouch packaging machine integrates filling systems for liquids, semi-solids, and particulates with sealing units that create strong closures.

After sealing, the pouches move into retort vessels for sterilization. Demand is growing. Producers targeting ambient-stable markets need to invest in such equipment now. For manufacturers, automation in retort pouch packaging cuts labor costs. It boosts output. It also ensures compliance with strict food safety standards.

FAQs about retort pouch packaging

What is a retort pouch?

A laminated, heat-resistant package used to sterilize and store food safely at room temperature.

How long does retort pouch food last?

Typically 12 to 24 months, depending on product and processing conditions.

How does retort differ from aseptic packaging?

Retort sterilizes food and package together, while aseptic packaging sterilizes them separately before filling.

What are common retort packaging examples?

Ready meals, soups, seafood, sauces, pet food, and retort trays.

What equipment is needed?

A retort pouch packaging machine that integrates filling, sealing, and sterilization functions.

Conclusion: Why retortable pouches are here to stay

Retortable pouches provide evident advantages over cans and jars, such as a longer shelf life and easier shipping. They mix the safety of old-fashioned processes with the flexibility and speed that modern food systems need.

That's why more food makers are working with MTPak Packaging. Our team makes custom retort pouches and trays that exceed safety regulations around the world, work well on retort pouch packaging equipment, and show off your brand with high-quality printing.

Contact MTPak (https://mtpak.com) today to ask for samples, learn about eco-friendly materials, or start your next packaging project.