Shrink Film Rolls: Essential Guide to Shrink Wrap Uses and Benefits

Shrink wrap is ubiquitous in our daily lives, yet this technology holds many hidden secrets.

In everyday life, we often see wholesale express parcels, neatly bundled bottled beverages on supermarket shelves, and dust-proofing household appliances before leaving the factory—all of these shrink wrap applications rely on shrink film rolls. For businesses, choosing the right shrink wrap not only solves shipping damage and time-consuming packaging issues but also reduces long-term costs.

Based on MTPAK's years of experience in flexible packaging services, this article will examine the principles of shrink wrap, its advantages, types, and applications, and help you determine the right shrink wrap solution.

What is Shrink Wrap?

Unlike ordinary plastic film, shrink wrap utilizes the film's ability to shrink when heated, allowing it to fit tightly to the container. It has a wide range of applications, including PET bottles for foods like soft drinks and seasonings, cosmetics, pharmaceuticals, and daily necessities.

The core structure of shrink wrap is shrink film, a plastic film with specialized properties typically made from polyolefin (POF), polyvinyl chloride (PVC), or polyethylene (PE).

In practice, shrink film rolls are first wrapped around the product or goods. Heat is then applied using a heat gun or shrink machine to cause the film to shrink. This process securely holds single or multiple items together, improving shipping stability while saving packaging space.

Compared to traditional cartons, tape, or strapping, shrink film rolls offer a distinct advantage: they are both lightweight and strong, ensuring protection while reducing excess weight. This is a valuable solution for businesses seeking shipping efficiency and lowering logistics costs.

What are the advantages of shrink wrap?

The wide application of shrink film rolls is not accidental. It has unique advantages in many aspects.

First, it offers strong protective properties. After shrinking by heating, shrink film covers the surface of the goods, preventing dust, moisture, and external friction from directly contacting the product. This type of packaging also helps identify whether the shrink wrap has been opened. For example, electronic components are extremely susceptible to moisture and damage during transportation. Using shrink wrap can significantly reduce scrap rates.

Secondly, it offers excellent transport stability. When packaging multiple products, shrink film rolls can help consolidate small items into a single unit, keeping them stable on pallets or shelves. This eliminates the need for boxes, tape, and other materials, and reduces the hassle of sealing. Beverage companies often use shrink film rolls to secure mineral water bottles or soda cans, preventing them from falling apart during transportation.

Third, it offers an excellent display. Clear shrink film rolls allow products to remain clearly visible at retail. The large display area allows for rich presentation, just like the product itself. This is particularly helpful for companies that need to highlight packaging design or brand identity. Consumers can directly see the product, which enhances trust and facilitates identification.

Finally, there are significant cost advantages. Compared to traditional packaging methods like cartons and wooden boxes, shrink film rolls use less material and are lighter, which can reduce logistics and transportation costs. For companies shipping large quantities, saving even a few grams of packaging weight per item can add up to significant cost savings.

More importantly, shrink wrap labels are easy to remove, making them easier to sort for trash. Compared to bottles with labels printed directly on the container, shrink wrap is easier to recycle. Because the packaging isn't printed directly on the container, the printed content can be changed at any time to accommodate new product launches or e-commerce discount seasons, making it particularly suitable for flexible product development.

What are the different materials of shrink film rolls in shrink wrap?

Shrink film rolls are not a single product, but are divided into different types according to the material and usage requirements. Common types include:

PE Shrink Film Roll

Polyethylene (PE) shrink film roll is thick and tough, making it commonly used for packaging large items such as beverage cases, building materials, and palletized cargo. Its superior protective properties make it suitable for industrial and logistics applications.

PVC Shrink Film Roll

Polyvinyl chloride (PVC) shrink film rolls offer excellent transparency, are rainproof, fire-resistant, antistatic, and easy to form. They offer low investment and high yield, making them a popular choice for packaging books, CDs, gifts, and other products. However, due to their limited environmental performance and low-temperature resistance, they are gradually being replaced by POF and PET.

POF Shrink Film Roll

Polyolefin shrink film (POF) offers a soft, uniform shrinkage rate, is environmentally friendly, and is non-toxic. It represents an alternative to traditional PVC heat shrink film and is suitable for direct food contact. It is commonly used for packaging frozen foods, bread, snacks, and pharmaceuticals. Its high transparency allows for excellent product display, making it a top choice for the food and retail industries.

PET Shrink Film Roll

PET shrink film rolls are a new type of heat-shrinkable packaging material. Due to its recyclability, non-toxicity, odorlessness, excellent mechanical properties, and environmental friendliness, PET has become an ideal alternative to polyvinyl chloride (PVC) heat-shrinkable film in developed countries. It is currently widely used in the pharmaceutical and cosmetics industries.

Shrink wrap made of different materials has its own advantages and disadvantages. Companies need to consider the packaging object, transportation environment, and budget when choosing.

What are the applications of shrink film rolls in life?

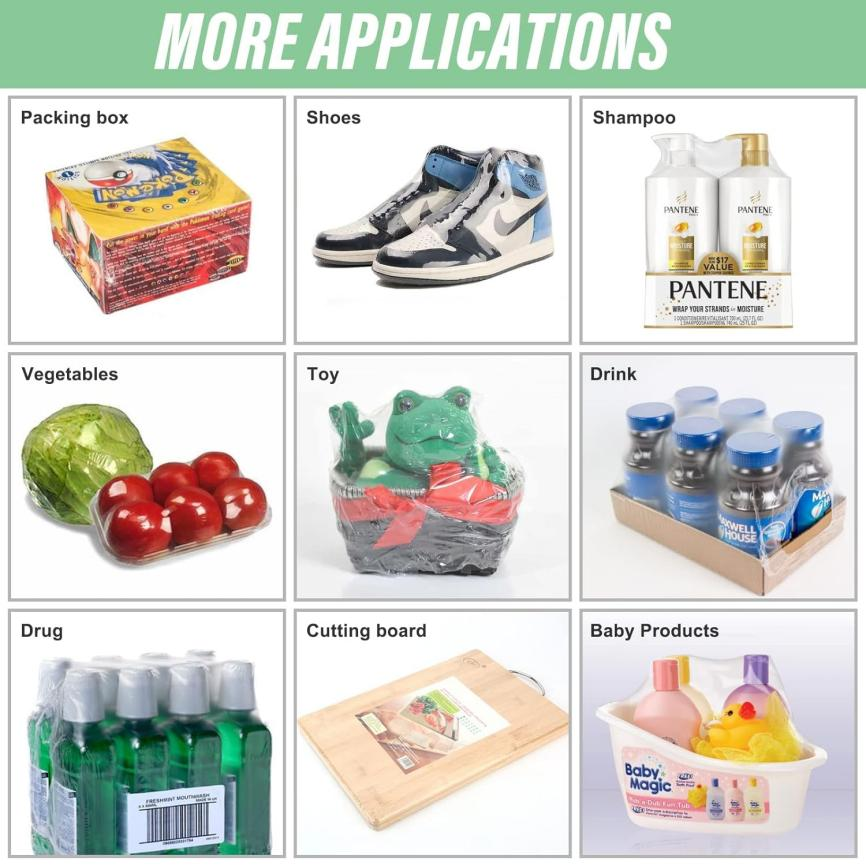

Shrink film rolls are a versatile material used in a wide range of applications, covering almost all industries that require transportation and storage.

In the food industry, shrink wrap is commonly used for packaging bottled beverages, snack bags, frozen meats, and ready-to-eat meal boxes, not only maintaining cleanliness but also extending shelf life.

In retail and e-commerce, sellers use shrink wrap to package promotional sets or bundled products, enhancing sales convenience while providing customers with a superior value experience.

In the industrial sector, large PE shrink film rolls are used to secure palletized goods, ensuring they remain stable during handling, loading and unloading, and long-distance transportation.

In the printing and publishing industry, shrink film rolls protect books, magazines, and brochures from moisture and wear during transportation.

In pharmaceutical and electronic product packaging, shrink film rolls provide additional protection by insulating against moisture and dust.

It is no exaggeration to say that shrink wrap is no longer just an auxiliary material, but an important part of improving efficiency and ensuring quality in the modern supply chain.

Conclusion

Overall, shrink wrap has become an essential material in the modern packaging industry thanks to its powerful protective properties, excellent display effects, and flexible application scenarios. From food retail to industrial packaging, from e-commerce shipping to printing and publishing, they are ubiquitous.

Choosing the right shrink wrap is crucial for companies seeking to improve packaging efficiency while balancing environmental protection and brand value. MTPAK offers shrink film rolls in a variety of sizes and materials, customizing sizes and thicknesses to meet specific customer needs. We also support environmentally friendly solutions, helping brands enhance their sustainable image while ensuring safe transportation.

If you are looking for a reliable shrink wrap supplier, MTPAK will be a trustworthy partner.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak