Insight into Different Types of Flexible Pouches

Nowadays, the market for consumer goods has become more and more competitive, and more new packaging now uses flexible pouches. They are popular because materials can adapt, they work in many ways, and they are sustainable. It is important for brands to combine product protection, good shelf look, and also environmental care. At MTPak, we use advanced materials and design to offer tailored pouch options. These answer high technical and market expectations in fields like food, drinks, and pet products.

This guide will explore the various types of flexible pouches, their benefits, customization options, and how to select the ideal packaging for your product.

Why Are Flexible Pouches Dominating Modern Packaging?

Flexible pouches are made of flexible, multi-material laminates that frequently include layers of PET, PE, PP, foil, or eco-friendly materials. These materials create great barriers while keeping the product very light.

This means big savings on shipping and storage expenses, reduced carbon footprint, and unlimited design opportunities are exceptional for brands, in terms of allowing them to create excellent shelf presence and maintain the integrity of their product from production to consumption.

What Are the Different Types of Flexible Pouches?

The market has different types of pouches. Each type is made for different uses and products. We can group them by their shape and what they are made of.

Classified by Pouch Style

We can classify pouches by their style, with many structural designs. Each one fits special product needs and market uses. Here is a simple list of the most common pouch styles and what makes each one good.

1. Stand-Up Pouches (Doypack)

Stand-up pouches use a special flat bottom. Because of this, they can stand straight on store shelves. This improves how much you see the product and the brand. These pouches often include easy-to-use zippers. They are good for many items like snacks, coffee, and pet food.

2. Spout Pouches

Spout pouches have a built-in pour spout. They usually come with a cap that can be closed again. This makes it easy to pour things out without spilling. These pouches work well for liquids, drinks, cooking oil, soaps, and thick things like sauces.

3. Gusseted Pouches

Gusseted pouches have folds on the sides or bottom. These folds can expand. That means there is more room for big or loose items. The pouch can hold more but still stays flat when stored. It is a good choice for powder, flour, rice, and small hardware products.

4. Flat Pouches (Pillow/Sachet)

Flat pouches are simple and cheap packaging. They lie flat when empty and they are sealed on three or four sides. People often use them for single-serve items, small samples, condiments, and light candy.

5. Retort Pouches

Retort pouches are made of strong layers. These layers can handle high heat. So these pouches are a good choice instead of cans or jars. They pack ready-to-eat meals, pet food, seafood, and other foods that need to last long.

Classified by Material & Special Function

Pouch styles define structure, materials define protection, feel, and environmental impact.

Below is a concise overview of key material categories and functional enhancements available in flexible pouch packaging:

| Type | Key Features | Ideal Use |

|---|---|---|

| High-Barrier Laminates | Excellent oxygen and moisture barrier properties. | Extending shelf life of sensitive products like coffee. |

| Kraft Paper | Natural, sustainable look often with compostable liner. | Eco-friendly branding for dry goods and artisanal products. |

| Recyclable Polyolefin Films | Monomaterial design for easy recycling. | Supporting circular economy goals for various products. |

| Child-Resistant (CR) Pouches | Complex opening mechanism for safety compliance. | Pharmaceuticals, cannabis, and hazardous substances. |

| Tamper-Evident Pouches | Visible, irreversible seals to show product integrity. | Ensuring safety for pharmaceuticals and premium goods. |

What Benefits Do Flexible Pouches Offer?

There are significant business benefits to switching to flexible packaging. It helps make more money. Also, it makes the brand look better by adding more eco-friendly elements and making the store more appealing.

• Cost and Logistics Efficiency: These shipments are incredibly light, which makes shipping costs much lower. They also make it easier to use and store pallets.

• Better Protection for Products: New materials and sealing procedures keep out light, moisture, and oxygen. That makes the product last a lot longer.

• Enhanced Sustainability: One big benefit is that it uses less material than rigid packaging. Using materials that can be composted (ASTM D6400) or recycled also has less of an impact on the environment.

• Maximum Brand Impact: High-quality, large printing surfaces let you make graphics and messages that attract people's eyes. This makes things stand out in markets where there are a lot of other options.

What Customization Options Are Available?

Customizing turns a basic pouch into something that shows your brand. MTPak provides many types of useful and visual improvements:

• Closures: Options are zippers you can reseal (press-to-close or slider styles), easy-tear notches, and spouts with caps to block dust.

• Fitments: There are also fitments. Examples are pour spouts, caps for dispensing, and fitments made for liquids or thick products.

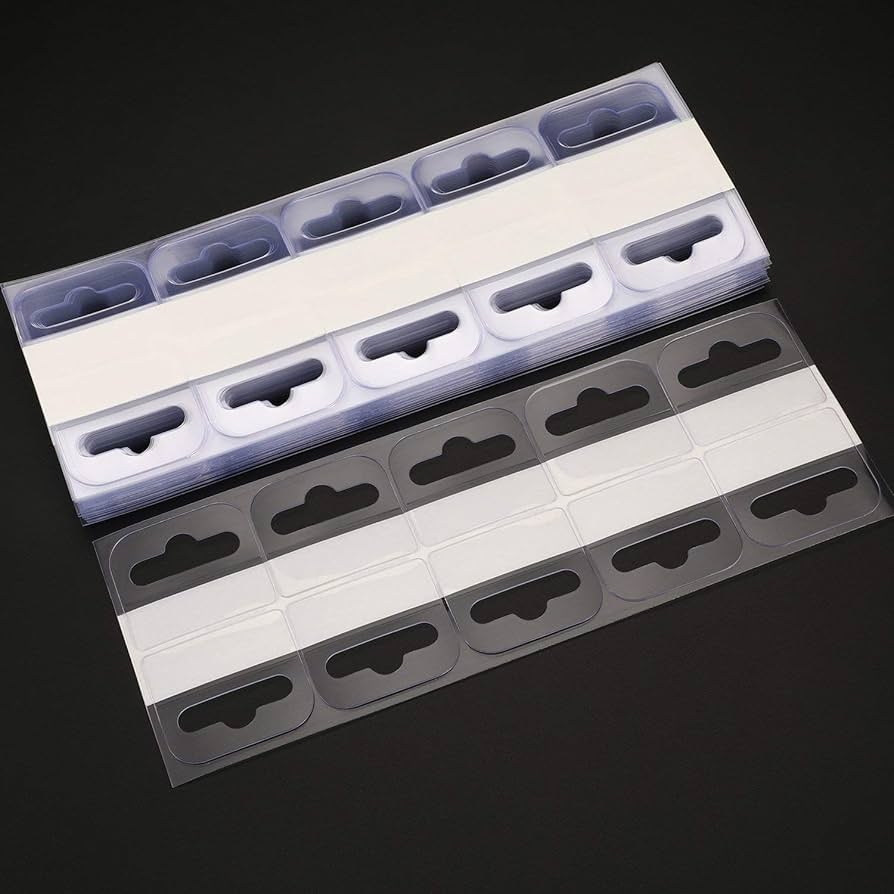

• Structural Features: Another option is structural features. These can be hang holes for store displays, round corners for safety, and clear windows so you can see the product.

• Finishing Effects: Finally, you choose the finish. You can pick glossy, matte, soft-touch, or metalized looks to get the style you want.

How to Select the Ideal Flexible Pouch for Your Product?

Selecting a pouch is a key decision. Here’s how to make sure you succeed:

Start by studying your product. Decide how much protection it needs from air or moisture. Consider its weight, oil, and how easily it gets scratched.

After that, think about your buyers. Understand what they prefer — resealable tops, earth-friendly packs, and attractive looks.

You also need to follow regulations. Be certain all materials are approved for food (under FDA or EU laws) and any other special standards.

Finally, team up with a skilled maker. Go with a partner like MTPak. They are experts in materials, printing, and sustainable options. They’ll help you through picking and designing.

Conclusion

Choosing the correct flexible pouch is a complicated procedure that has a direct effect on how well a product does. It includes protection, sustainability, branding, and making things easier for customers.

At MTPak, we use our years of experience in the flexible packaging business to give each client the best possible solutions. We have experts on staff who can make sure that the best materials are used, the printing is high-definition, and the functional elements are added, all while following strict international safety and sustainability criteria (such as FDA, EU, and FSC certifications). Let us help you make packaging that keeps your product safe and boosts your brand.

Are you ready to look into custom flexible pouch options? Get in touch with our packaging specialists immediately!

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak

FAQ

1. Can you recycle flexible pouches with zippers?

It depends on the kind of material. Monomaterial polyolefin bags with zippers that work with them are made to be recycled. The consumer may need to detach the zipper for complicated laminates.

2. What other eco-friendly materials are there besides recyclable plastics?

At MTPak, we have a lot of different options, such as pouches produced with certified biodegradable films (where applicable), paper from sustainable forests that are FSC/PEFC-certified, and solutions that use post-consumer recycled (PCR) content.

3. How long does it usually take to make personalized pouches?

At MTPak, the time it takes to get an order varies depending on how complicated it is and how many there are. It usually takes 3 to 5 weeks to make a prototype and start production for custom designs. During the project quote phase, we give you reliable timelines.