Guide to Understanding The Use of Corrugated Cardboard in Packaging

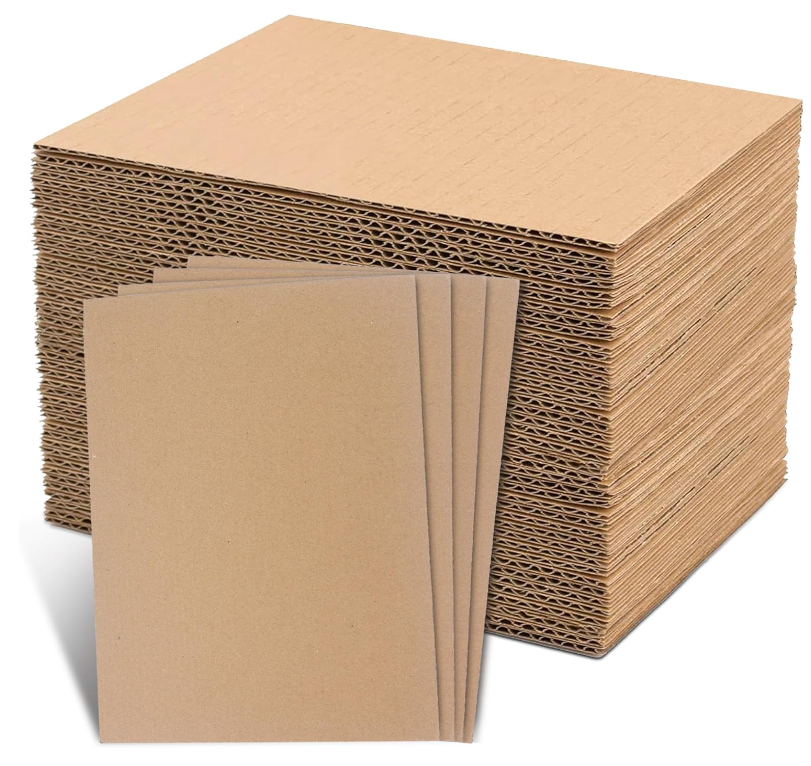

When it comes to packaging, few materials have shaped modern logistics as profoundly as corrugated cardboard. From e-commerce parcels to industrial shipments, this versatile material has quietly become the backbone of safe and efficient delivery. At first glance, a sheet of corrugated cardboard may seem simple, yet behind its wave-like structure lies a combination of engineering and science. Those carefully designed flutes not only absorb impact but also provide remarkable strength without adding excessive weight.

At MTPAK, we understand that choosing the right packaging goes beyond picking a material. Our team works closely with brands to design customized solutions, whether it involves corrugated cardboard, flexible pouches, or other soft packaging formats. By combining first-hand production experience with technical know-how, we help businesses select the right specifications, optimize protection, and maintain a sustainable footprint.

Corrugated cardboard’s versatility extends beyond standard boxes—it can be used for creative displays, temporary furniture, and other unexpected applications. Its adaptability, combined with recyclability and renewable content, makes it a go-to solution for companies seeking reliable and eco-friendly packaging. In this guide, we will explore what corrugated cardboard is, its hidden strengths, how to choose the right specifications, and why it has earned its place as the preferred choice for modern packaging, with insights drawn from MTPAK’s hands-on experience in helping clients across industries.

What is corrugated paper?

If you've ever curiously torn open a cardboard box, you'll discover that the middle layer isn't solid cardboard, but rather a wave-like structure—the core secret of corrugated paper. This wavy sandwich structure is a masterpiece of materials engineering: by sandwiching a wavy paper core between two layers of liner paper, it creates countless tiny support cells. When pressure is applied, these waves act like springs to disperse and absorb the impact, giving the cardboard incredible compressive strength while remaining lightweight.

Even more astonishing is that this structure is inspired by the wisdom of nature—a hexagonal structure similar to a honeycomb, achieving maximum structural strength with minimal material. It is this biomimetic design that allows corrugated cardboard to carry items several times its own weight with its lightness, making it a heavyweight in the packaging world.

What are some unknown uses of corrugated cardboard?

Beyond its traditional role as a carrier for packages, corrugated cardboard is demonstrating its remarkable cross-disciplinary appeal in various fields:

Innovative Applications in the Food Industry:

Corrugated cardboard has become a smart food steward—cardboard trays with a special food-grade coating absorb excess moisture from fresh produce while extending its shelf life through breathable design. Innovators are even turning corrugated cardboard into biodegradable food insulated boxes lined with eco-friendly insulation, making food delivery both environmentally friendly and efficient. In the high-end food packaging sector, delicately embossed micro-corrugated boxes are replacing traditional gift boxes, providing a luxurious level of protection and display for delicate foods like chocolate and pastries.

An Artistic Revolution in the Cultural and Creative Industry:

Corrugated cardboard has found new life in the hands of creative professionals—architects use it to create architectural models, artists transform it into large-scale installations, and designers develop modular corrugated cardboard furniture. These creations are not only lightweight and environmentally friendly, but also showcase the unique warmth and texture of paper. In education, corrugated cardboard has become an ideal material for STEAM programs, allowing students to understand structural mechanics and sustainable design through hands-on crafting.

Fashion's eco-friendly statement:

Avant-garde designers are transforming corrugated cardboard into wearable art—using special treatments to make it flexible and then applying sophisticated tailoring techniques to create stunning pieces. These seemingly fragile paper garments are capable of withstanding hours of display, using the simplest of materials to convey profound sustainable fashion concepts.

Green innovations in agriculture:

Corrugated cardboard is even finding its way into farmland—as a biodegradable weed suppressant mat, effectively preventing weed growth and absorbing into the soil after the season. Some innovators are even embedding seeds directly into the cardboard, allowing the packaging to grow flowers and plants after use, creating a true "packaging-to-life" cycle.

These groundbreaking applications prove that corrugated cardboard is no longer just a simple packaging material but has become a magical material that connects sustainable development and innovative design. Its possibilities are limited only by our imagination, and it is writing new legends in every unexpected field.

How to choose the appropriate corrugated cardboard specifications and models?

Classification by corrugated type: The corrugated type is determined by the peak height and number of teeth. Different types have significant differences in cushioning, support, and thickness. The following values are for reference only.

Type A corrugated paper: Peak height is approximately 4.5-5mm, with a minimum of approximately 32 teeth per meter. It offers the best cushioning properties and is suitable for packaging fragile items such as ceramic tableware and glassware, but it is not suitable for express delivery.

Type B corrugated paper: Peak height is approximately 2.5-3mm, with a maximum of approximately 50 teeth per meter. It offers the strongest support and is suitable for heavy-duty products such as home appliances and large food boxes, while also saving storage space.

Type C corrugated paper: With a peak height of approximately 3.5-4mm and a tooth count of approximately 40 per meter, it is between Types A and B, offering a balance of cushioning and support. It is the most versatile type and is suitable for most daily necessities and food packaging.

Type E corrugated paper: Peak height is lower, approximately 1.1-1.4mm, with a higher number of teeth, approximately 100 per meter. It is thinner and has a smoother surface, making it suitable for express delivery boxes and small packages such as cosmetic sample boxes, and it offers excellent printing results.

Classification by number of layers:

The three-layer (face tissue + core paper + lining paper) offers a lighter load capacity and is suitable for clothing and snacks.

Five-layer (with middle paper and core paper) offers a greater load capacity and is suitable for appliance parts and bottled beverages.

Seven-layer offers the highest load capacity and is suitable for large appliances and industrial parts.

Classification by Weight:

Paper weight is the "mass index" of corrugated cardboard.

Lightweight (200-250gsm) is suitable for soft goods such as clothing and textiles.

Mediumweight (250-300gsm) meets the packaging needs of most daily necessities.

Heavyweight (300-400gsm) acts as protective armor for heavy equipment, providing solid protection for mechanical parts, glassware, and more.

Ultra-heavyweight (400gsm and above) is specifically designed for extreme transportation conditions.

Why is corrugated cardboard the first choice for sustainable packaging?

In this environmentally conscious era, corrugated cardboard demonstrates remarkable green credentials: its raw materials are derived from renewable resources and have a very high recycling rate, truly achieving a cradle-to-cradle circular economy.

More importantly, the life cycle of corrugated cardboard resembles a perfect cycle: after use, with simple processing, it can be recycled into new paper products and even reused multiple times. This recyclability, combined with the transportation savings brought about by its lightweight design, makes corrugated cardboard one of the packaging materials with the lowest carbon footprint.

Modern corrugated cardboard factories are exemplary examples of green manufacturing, utilizing solar power generation, closed-loop water recycling systems, and even converting production waste into biomass fuel, incorporating sustainable development concepts into every production process.

Conclusion

The story of corrugated cardboard shows us that the greatest innovations often lie within the simplest structures. Those undulating lines are more than just wrinkles in the material; they represent a beautiful resonance between human wisdom and natural inspiration. From protecting a fragile gift to supporting entire logistics systems, corrugated cardboard, in its simplest form, safeguards every aspect of modern life.

To learn more about innovative packaging solutions, please contact the professional team at MTPAK. Let us apply our expertise in materials science and engineering to create the most suitable packaging for your product.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak