Guide to Purchasing Food Plastic Cling Wrap: How to Choose A Safe and Efficient Preservation Solution for Your Products?

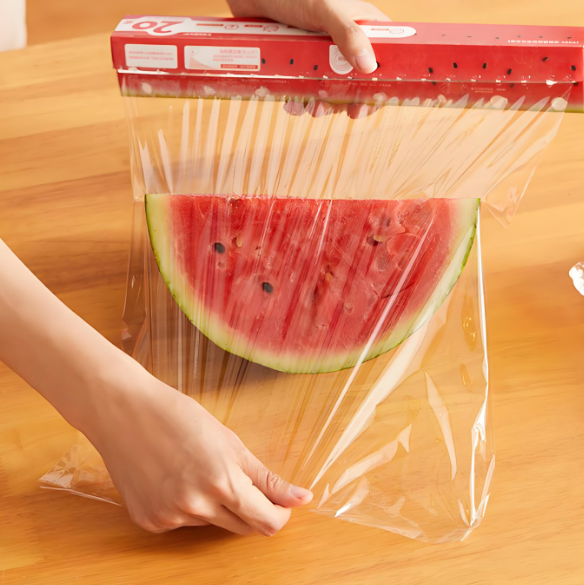

In the food packaging and catering industries, plastic wrap is a critical component for locking in moisture, preventing odor transfer, and extending shelf life.

However, with a wide variety of plastic wrap options available on the market, including PVC and PE, are you concerned about safety, suitability, and environmental issues? An inappropriate choice could alter food flavor or even pose a safety risk.

As a provider of customized food-grade flexible packaging solutions, MTPAK, with its deep understanding of materials science and regulations, will help you navigate this complex landscape and make the most professional and safe choice.

What are the core functions and performance indicators of plastic cling wrap?

The core mission of plastic cling wrap is to form a protective barrier on the surface of food. Its performance is primarily measured by the following key indicators:

- Oxygen Transmission Rate (OTR): It measures the ability of plastic wrap to block oxygen. The lower the OTR value, the more effective it is in preventing food oxidation and deterioration, such as fruit discoloration and oil rancidity.

- Water Vapor Transmission Rate (WVTR): It measures the ability of cling film to block water vapor. The lower the WVTR value, the more effectively it can prevent water loss from food, keep fruits and vegetables fresh and tender, and avoid dried cooked food.

- Light Transmittance and Haze: They affect the display effect of the product. High light transmittance shows the true color of the ingredients, while high haze can soften the light.

- Self-adhesive (Cling): Ensure that the film can adhere closely to the surfaces of containers and ingredients of different shapes, forming an effective seal.

- Temperature resistance: determines whether it is suitable for scenarios such as microwave heating or low-temperature freezing.

Special note on safety (plasticizers)

The production of PVC cling film necessitates the addition of plasticizers (such as DEHP) to make it soft. These plasticizers pose a risk of migrating into food, especially when in contact with oily foods or when heated.

Therefore, many countries and regions have strict restrictions on their use. PE and PVDC cling films do not require the addition of plasticizers, making them safer and more reliable choices. Furthermore, all materials must comply with food contact material regulations such as FDA 21 CFR or EU 10/2011.

What are the precautions for choosing and using plastic cling wrap?

- Misusing ordinary PVC plastic wrap for microwave heating can cause plasticizer migration and film melting.

- The best stickiness does not necessarily equate to the best preservation effect. PVDC has general stickiness but top-level barrier properties, while PE has moderate stickiness but high safety and microwave resistance.

- PE cling film is usually printed with the LDPE-4 recycling symbol. Although it is theoretically recyclable, due to pollution and morphological issues, it is difficult to recycle in practice, and its use should be minimized.

Is your preservation solution keeping up with the times?

With consumers' increasing focus on health and environmental protection, the plastic wrap market is experiencing two major trends: Firstly, the market share of PVC plastic wrap is gradually being replaced by safer PE and PVDC; secondly, biodegradable plastic wrap made from degradable materials (such as PLA+PBAT) has begun to emerge, but its barrier properties and cost remain challenges.

Conclusion

Choosing the right plastic cling wrap is crucial for food safety, consumer health, and brand responsibility. Compared to film materials with high safety risks, materials such as PE or PVDC, which are safer, more oil-resistant, and have higher thermal stability, are more suitable for use as food-grade plastic cling wrap. It can be believed that this will also be a clear technological and future market trend.

MTPAK is a professional service provider of customized food-grade flexible packaging solutions. We not only offer material expertise but also deliver innovative, comprehensive packaging solutions. From barrier films to microwave-safe lidding films, we are committed to safeguarding your products with our professional knowledge and authoritative compliance standards.

Are you searching for superior freshness packaging for your food, catering, or fresh produce products? Contact MTPAK for professional material recommendations and customized solution samples, ensuring both safety and freshness.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak

*Some pictures are from the Internet. If there is any infringement, please get in touch with us to delete it. Thank you.