Digital Vs Flexo Printing for Flexible Packaging

Flexible packaging is a key part of modern retail since it is durable, easy to ship, and looks appealing on shelves. For brands, though, the way they print can be just as significant as the material itself. Should you pick digital printing flexible packaging for speed and flexibility, or flexographic printing for low-cost high-volume printing?

We use both digital and flexographic printing at MTPAK to assist businesses identify the best way to reach their brand goals. This article talks about the pros and cons of digital and flexo printing for flexible packaging, as well as when to use each approach.

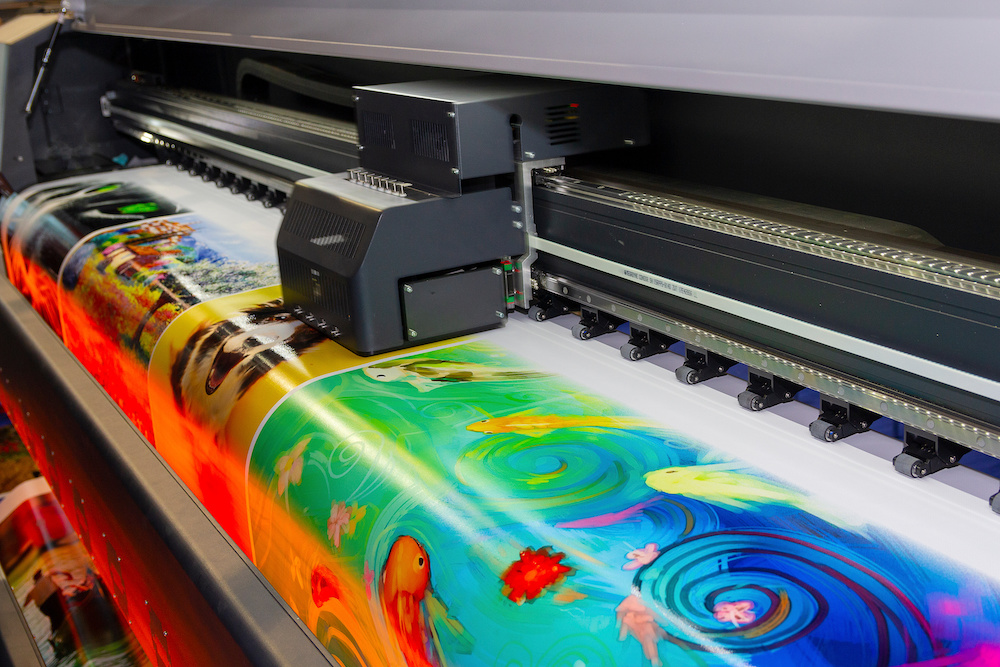

What is digital printing in flexible packaging?

Digital printing employs designs from digital data to print directly on the film that wraps the package. This means you don't need plates or cylinders. This makes it very beneficial for organizations who need to print small to medium amounts of products, change designs often, or use patterns that are only accessible at particular periods of the year. You can also print variable data, like QR codes or custom art, which is becoming more and more useful for marketing directly to customers.

Digital printing flexible packaging is quick, simple to adapt, and generates high-quality things with minimal effort.

| Pros of Digital Printing | Cons of Digital Printing |

|---|---|

| No need for plates or cylinders | More expensive per unit for big production |

| Quick turnaround | Not extremely cost-effective for very large numbers |

| Supports data that can change (QR codes, customization) | Some substrates may not work well with each other |

| Images with a lot of detail and bright hues | Not necessarily as long-lasting for printing on a very wide scale |

| Good for short to medium runs and designs that change with the seasons | - |

What is flexographic printing in flexible packaging?

Flexographic printing, or flexo, uses flexible relief plates to place ink on films that are used to package things. Printing on flexible packaging, this technique is very popular, especially for large-scale production. Making plates for each design is part of the setup phase. Once they are ready, though, flexo makes the same high-quality, low-cost outcomes for big batches every time.

Flexographic printing may employ a wide range of inks and substrates; therefore it can be used for a wide range of things, such as food pouches and personal care packaging.

| Pros of Flexographic Printing | Cons of Flexographic Printing |

|---|---|

| Cost-effective for large-scale production | Expensive setup costs |

| Consistent quality across lengthy runs | Slower initial setup than digital |

| Works with a wide variety of substrates and inks | Less adaptable when upgrading or modifying designs |

| Durable prints are ideal for packaging that requires resilience | Slightly less detail than digital printing |

| Economical over time when produced at scale | Plate-making increases material and time loss |

Digital vs Flexo Printing: What are the key differences?

Both ways work, but which one is better depends on how big the production is and what the branding demands are. This is a comparison of digital and flexo printing for flexible packaging.

| Factor | Digital Printing | Flexographic Printing |

|---|---|---|

| Setup | No plates or cylinders required | Requires printing plates |

| Cost efficiency | Best for small to medium runs | Best for large-volume runs |

| Turnaround time | 10–14 working days | 6–12 weeks |

| Print quality | Very high, offset-like | High, consistent, slightly less detail |

| Flexibility | Easy to update designs, supports variable data | Fixed designs once plates are made |

| Volumes | 250 – 100,000 pcs | 100,000 – millions |

Case Example: Coffee roaster balancing digital and flexo

MTPAK partnered with a specialized coffee roaster to try out alternative printing choices. The roaster used digital printing flexible packaging for its limited-edition seasonal blends. This made it possible to make tiny batches with bright patterns. The roaster converted to flexo printing for its primary product line, which it sells all year. This cuts the cost per unit while keeping quality the same.

Result: By using both technologies in a smart way, the roaster was able to offer new blends faster and cut overall packaging costs.

FAQs about printing flexible packaging

1. What is digital printing in flexible packaging?

Digital printing flexible packaging is the process of putting designs directly from digital files onto packaging films without utilizing plates.

2. What is flexographic printing in packaging?

Flexographic printing is best for large runs because it uses flexible relief plates to move ink.

3. Which is better: digital vs flexo printing?

Neither is superior in and of itself. Digital is ideal for short runs and flexibility, while flexo is excellent for huge volumes and low costs.

4. Can both methods be used by one brand?

Yes. A lot of firms utilize digital printing for limited editions and flexo for their main product lines.

Conclusion: Work with MTPAK for the right flexible packaging printing

Digital and flexographic printing both have their pros and cons. The ideal choice for you will depend on how many copies you need, how quickly you need them, and what your branding demands are. Businesses may make smart choices that take into account cost, quality, and flexibility by knowing the distinctions between digital and flexo printing.

At MTPAK, we provide both digital printing flexible packaging and flexo printing solutions. This lets companies get high-definition results on a wide range of surfaces. obtain in touch with us today to ask for samples, compare ideas, or obtain a quote for your next packing job.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak