Did You Choose The Wrong Paking Tape? MTPAK's Multi-scenario Solution Helps You Avoid Pitfalls

From package packaging in e-commerce warehouses to component fixation in manufacturing, to gift box sealing in retail, packing tape is a fundamental yet crucial auxiliary material that runs through multiple industries' logistics and packaging processes.

However, most companies often encounter problems due to underestimating tape selection, such as DTC merchants may cause package damage during transportation due to insufficient tape adhesion, factories may cause outdoor stored parts to become damp due to poor tape weather resistance, and brand owners may affect product appearance due to incompatible tape and packaging materials.

As a service provider specializing in customized solutions for flexible packaging, MTPAK not only provides highly adaptable flexible packaging products, but also outputs precise selection and usage plans for packaging tape based on pain points in different scenarios, reducing enterprise cost losses from details.

How to determine the core performance of paking tape?

The key to selecting the right packaging tape is to clarify whether its core performance matches the product transportation and storage scenarios. Different types of tapes have significant differences in adhesion, temperature resistance, aging resistance, and other indicators. If they are selected blindly, problems such as tape cracking in low-temperature environments and adhesive failure in a wet environment may occur, which directly affect the sealing of food packaging.

From the perspective of practical application scenarios, there are three core dimensions to consider when judging the performance of adhesive tape: firstly, adhesive force, usually measured in Newtons/25mm. The food and beverage industry recommends choosing adhesive tape with an adhesive force of ≥ 3.5N/25mm to ensure that it is not easily peeled off during stacking and transportation. Next is the temperature resistance range. If the product requires cold chain transportation, it is necessary to choose low-temperature adhesive tape with a temperature resistance range of -20 ℃~60 ℃ to avoid temperature fluctuations that may cause a decrease in tape performance; Finally, regarding the strength of the substrate, PET substrate tape has better tensile strength than PVC substrate and is more suitable for packaging weighing over 5kg, reducing the probability of tape breakage during transportation.

In addition, food contact compliance cannot be ignored. When MTPAK provides packaging solutions to customers, they will simultaneously verify the compliance certificate of the tape to ensure that everything from the packaging body to the sealing materials meets food safety standards.

What are the common types of paking tape? How to match industry scenarios?

There are many types of packaging tape on the market, and the applicable scenarios for different types vary greatly. Mismatching not only increases costs but may also cause damage to goods.

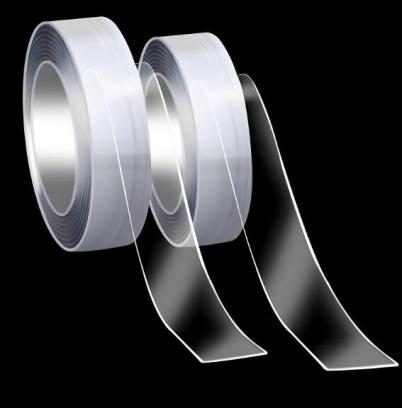

The core material of transparent acrylic tape is acrylic adhesive and a PET substrate. The core performance is strong adhesion (≥ 3.8N/25mm), good weather resistance and anti-aging. Suitable for carton packaging, electronic equipment outer box protection, and daily necessities packaging in e-commerce logistics.

The core materials of anti-static and flame-retardant tape are a conductive adhesive layer and a PET substrate. The core performance is surface resistance ≤ 10 ^ 9 Ω, UL94 V-0 flame retardant, and waterproof. Suitable for the transportation of circuit boards in the electronics industry and the packaging of precision instruments in medical equipment.

The core materials of kraft paper pressure-sensitive adhesive tape are water-based pressure-sensitive adhesive and kraft paper substrate. Its core performance is recyclability, strong compatibility with paper substrates, and easy tearing. Suitable for environmentally friendly packaging such as paper gift box packaging, food outer boxes, book packaging, and other scenarios.

The core materials of industrial high-strength adhesive tape are rubber adhesive and fiber cloth substrate. Its core performance is tensile strength ≥ 25MPa, temperature resistance range -30 ℃~80 ℃, and wear resistance. Suitable for fixing mechanical parts in heavy industry, packaging of building materials in the construction industry, and transportation protection of automotive parts.

How to improve the logistics efficiency of enterprises through collaborative optimization?

Packaging tape does not exist independently. Collaborative design with the packaging body can further reduce operating costs and improve logistics efficiency, especially for high-frequency shipping enterprises, where optimization space is significant. Collaborative optimization can start from three directions: tool adaptation, process standardization, and cost control.

Adaptation of tools and tape: Choose tools based on shipment volume to avoid manual inefficiency. E-commerce companies with an average daily shipment volume greater than 300 pieces can use tape cutters to shorten packaging time and thus shorten working hours. Industrial enterprises can use automatic tape winding machines when packaging large equipment, which can improve work efficiency and reduce tape waste.

Standardization of processes: Develop guidelines for the use of adhesive tape to avoid operational deviations. The specification needs to clarify the tape specifications, packaging methods, quality inspection, and establish a patrol mechanism. A certain proportion of packaging should be randomly inspected daily to confirm that the tape adhesion meets the standards and avoid damage to the goods due to operational errors.

Cost synergy control: Reduce costs through integrated procurement of packaging and tape. MTPAK can provide customized packaging and tape adaptation solutions for enterprises. On the one hand, it recommends tape width based on packaging size, and on the other hand, it reduces tape procurement costs through bulk purchasing.

Conclusion

Although packaging tape is an inconspicuous auxiliary material, it directly affects the damage rate, compliance, and logistics efficiency of enterprises. Whether in the e-commerce, manufacturing, retail, or outdoor industries, only by accurately matching scene requirements, avoiding usage errors, and doing a good job of collaborative optimization, can tape become a driving force for cost reduction and efficiency improvement, rather than a risk point.

MTPAK is always committed to providing customers with the highest quality flexible packaging products and services. Our R&D team continues to develop new tape materials to meet the special needs of different industries. No matter what packaging challenges you face, we can provide professional solutions.

Do you need a solution for packing tape? Please contact MTPAK for professional advice and free samples:

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak

FAQ

Q: What type of tape should be used in low-temperature environments?

A: Low-temperature-resistant acrylic adhesive tape should be selected, which can maintain adhesion in an environment of -40 ℃. It is recommended to preheat the tape and adhesive surface during use.

Q: What is the shelf life of the tape?

A: Generally 2 years, but it needs to be stored in a cool and dry place, away from direct sunlight and a high-temperature environment. A tape that has exceeded its shelf life may experience a decrease in adhesion.

Q: How should tape be used for special surfaces such as PE and PP?

A: Low surface energy materials require the use of special adhesive tape. It is recommended to first treat the surface (such as corona treatment) and use tape products specifically developed for low surface energy materials.