Desiccant Bags in Modern Packaging Solutions

In the packaging of food and consumer goods, moisture is often the most insidious destroyer. From transportation to the shelf, environmental humidity, temperature fluctuations, and storage conditions can all lead to product spoilage, clumping, mold, or flavor loss. For companies committed to quality and brand reputation, a single packaging failure means not just lost inventory, but potentially a loss of consumer trust.

Against this backdrop, desiccant bags have become an indispensable "silent guardian" in brand packaging. As a supplier focused on sustainable and high-performance packaging solutions, MTPAK is helping more and more brands reassess their moisture protection systems – moving beyond simply "adding a desiccant pack" to building more reliable packaging protection strategies through scientific design, material matching, and supply chain optimization.

What exactly are desiccant bags?

Imagine a product's long journey in a shipping container, accompanied by humidity – moisture from the air stealthily permeates the packaging, making biscuits soft, dulling coffee flavors, or causing powders to clump. Desiccant bags are precisely the small "guardians" designed to prevent these issues.

Unassuming in appearance, they carry the crucial responsibility of maintaining a dry internal environment. Inside these bags are materials with powerful moisture-absorbing capabilities. When moisture is present in the air, they rapidly capture and lock in these molecules, keeping the packaged space stable and clean.

Different types of desiccants are like experts in various fields:

l Silica Gel: Transparent beads, the versatile all-rounder of moisture absorption.

l Clay / Bentonite Desiccants: Based on natural clay, they are eco-friendly and economical.

l Molecular Sieves: React quickly, ideal for products extremely sensitive to humidity.

l Calcium Chloride: Known for its remarkable moisture capacity, particularly effective in high-humidity environments.

Externally, they are just small white bags; but in the microscopic world of brand packaging, they are the force that preserves quality.

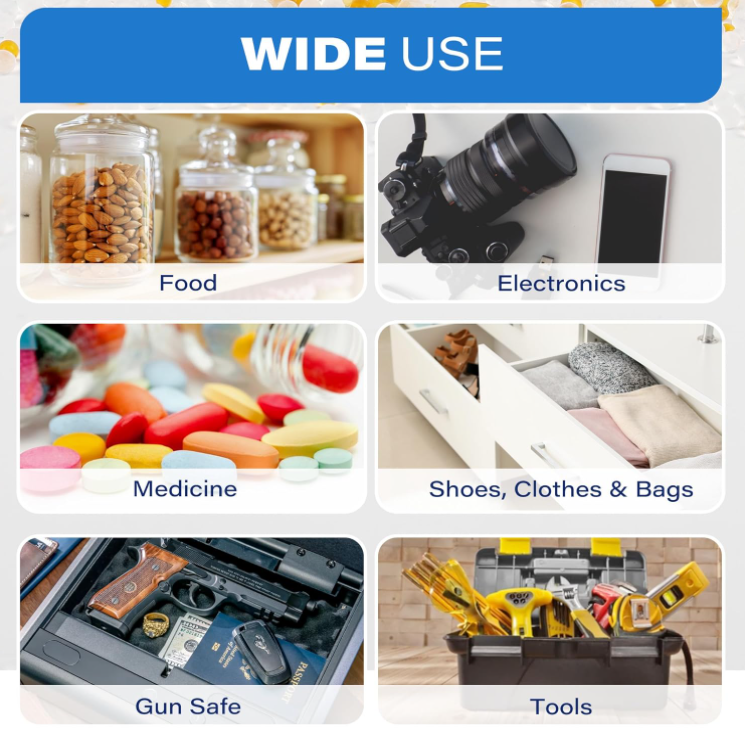

How are desiccant bags used in food packaging?

In the world of food packaging, desiccant bags act like silent "time managers" – they don't alter the product's taste but extend its freshness. Whether it's a bag of freshly baked biscuits, a box of aromatic coffee beans, or a pack of plump nuts, they are all engaged in a constant battle against airborne moisture.

When a desiccant bag is placed inside sealed packaging, it quietly begins absorbing moisture from the air, preventing spoilage caused by rising humidity. Biscuits stay crisp without becoming soggy, nuts' oils don't oxidize and mold, and coffee beans retain their aroma longer. For dried fruits, milk powder, or seasonings, it acts as a protective barrier against moisture and clumping, ensuring the product remains in ideal condition through transportation across seasons and climates.

In modern supply chains, products may undergo long transit times and complex storage conditions from production line to shelf. The presence of desiccant bags provides brands with an added layer of security in this race against time. It's not merely a packet of "moisture absorber" but a reflection of a brand's commitment to its product integrity. For food, freshness isn't just about taste; it's about trust.

Why must brands prioritize desiccant selection?

Different products, climates, and packaging environments have varying sensitivities to humidity. Choosing the wrong desiccant can not only render the protection ineffective but might even be counterproductive:

Excessive absorption capacity might over-dry the package, affecting food texture.

Insufficient capacity can lead to saturation and failure during long-distance shipping.

Non-compliant or cheap desiccant materials can pose safety and compliance risks.

Therefore, leading brands prefer partnering with professional packaging suppliers for moisture simulation testing and customized desiccant solution design, rather than relying on standardized, one-size-fits-all approaches.

What are the new trends in sustainable desiccant packaging?

With the growing emphasis on sustainability, traditional chemical desiccants are undergoing innovation. Future moisture protection systems will be more eco-friendly and intelligent:

Biodegradable Bags: Using plant-based fibers or bio-materials instead of traditional PE film, making desiccant bags easier to decompose.

Regenerable Desiccants: Can be reactivated at specific temperatures, reducing waste and long-term costs.

Smart Humidity Indicator Systems: Integrated humidity indicator cards or color-sensing technology allow brands and consumers to visually check if the desiccant is saturated.

Integrated Moisture Control Design: Incorporating moisture-absorbing layers directly into the packaging structure, creating an "invisible desiccant" solution.

What common misconceptions should be avoided when selecting desiccants?

Common misconceptions in the desiccant field include:

l More is always better: The amount should be precisely calculated based on headspace, product moisture content, and barrier material moisture vapor transmission rate.

l All desiccants are food-safe: Only silica gel and certain clays carry food-grade certifications.

l Placement doesn't matter: Avoid direct contact with the product and ensure air can circulate in the bag.

Conclusion

Desiccant bags may seem minor, but they are crucial to product quality, brand reputation, and supply chain stability. For any brand that values product experience and long-term development, moisture protection shouldn't be a reactive measure, but a strategic mindset.

MTPAK leverages professional material expertise, sustainable innovation, and industry experience to provide brands with integrated solutions – from packaging design to moisture protection optimization.

If your products still face moisture challenges during transit or storage, now is the time to reassess your moisture protection system – ensuring every package, inside and out, can withstand environmental challenges.

Need to Customize Your Moisture Protection Solution?

MTPAK offers sample packs containing various desiccant materials and sizes, accompanied by dosage calculation charts and integrated solutions to help you precisely control humidity levels within your packaging.

Contact MTPAK today for your tailored solution.

Email: account@mtpak.com

Contact us: https://mtpak.com/contact-mtpak