Are Polypropylene Plastic Products Harmful to the Human Body?

Plastic products are ubiquitous in our daily lives, from takeout containers and coffee cups to food packaging bags and beverage bottles. Have you ever wondered if these ubiquitous plastics are truly safe?

Polypropylene is one of the most common plastic materials used in food packaging, maternity and baby products, and everyday containers. However, questions about whether plastic is toxic and whether long-term exposure poses health risks continue to plague consumers and businesses. For the flexible food packaging industry in particular, the safety of polypropylene is directly linked to product quality and brand trust.

This article will examine the safety of polypropylene from a scientific perspective, analyze potential risks in practical application scenarios, provide practical safety identification methods, and explain how MTPAK creates safe and compliant polypropylene flexible packaging through rigorous raw material control and process optimization, helping you completely resolve your concerns.

Is polypropylene plastic toxic?

Polypropylene (PP) is a polymer material made from the monomer propylene. It is colorless, odorless, and non-toxic, and is generally considered one of the safest food contact materials currently available.

During the production process, only small amounts of catalysts and antioxidants are added to PP to ensure material stability. Most PP products do not contain any other chemical additives. Their high molecular weight, strong chemical inertness, and stable properties make them harmless to humans and food or beverages.

In fact, concerns about the safety of plastics generally stem from three aspects:

First, some plastics can decompose into harmful small molecules under high temperatures and aging conditions. For example, polycarbonate (PC) baby bottles have raised concerns about the potential release of bisphenol A, but PP does not pose similar problems.

Second, there is the risk of plasticizers. While some plastics require plasticizers to enhance flexibility, PP plastics do not require them during their synthesis and contain only minimal catalysts and antioxidants, which are so low that they are negligible.

Finally, there is the issue of microplastics, which has received considerable attention in recent years. Once discarded, plastic slowly decomposes in the environment, forming tiny particles that enter the human body through the food chain. While current research hasn't fully determined its long-term health effects, it does serve as a reminder to prioritize plastic recycling and reuse.

In short, addressing the issues of white pollution and microplastics fundamentally requires reducing plastic pollution at the source and improving recycling efficiency, such as requiring proper waste sorting. Starting small.

Are all polypropylene plastic products safe?

Although pure polypropylene is safe, some companies, to reduce costs, add hazardous substances or misuse recycled materials during production, leading to safety risks in PP products. These non-compliant practices are key areas consumers should be wary of.

1. Adding Harmful Plasticizers and Stabilizers

To enhance the flexibility or aging resistance of PP products, some manufacturers add harmful substances such as phthalates (plasticizers) and lead salt stabilizers. These substances can disrupt the human endocrine system, especially harming infants and young children.

2. Misuse of Recycled Materials, Especially Non-Food-Grade Recycled Materials

Some companies recycle industrial waste plastics (such as pesticide bottles and motor oil drums) into PP pellets for use in food packaging. Industrial waste plastics may contain pesticide residues, heavy metals, and organic solvents, which cannot be completely removed even through recycling and can migrate into food products through contact.

3. Abuse of high temperatures beyond safety limits

Although PP can withstand short-term temperatures of 120°C, prolonged exposure to temperatures exceeding 160°C (such as microwave heating close to the heating element) or repeated high-temperature use (such as heating a PP lunch box more than three times a day) can cause the PP molecular chains to break, releasing trace amounts of propylene monomer. While the amount released in a single exposure is extremely low, long-term accumulation poses a potential risk.

How to tell if plastic material is safe?

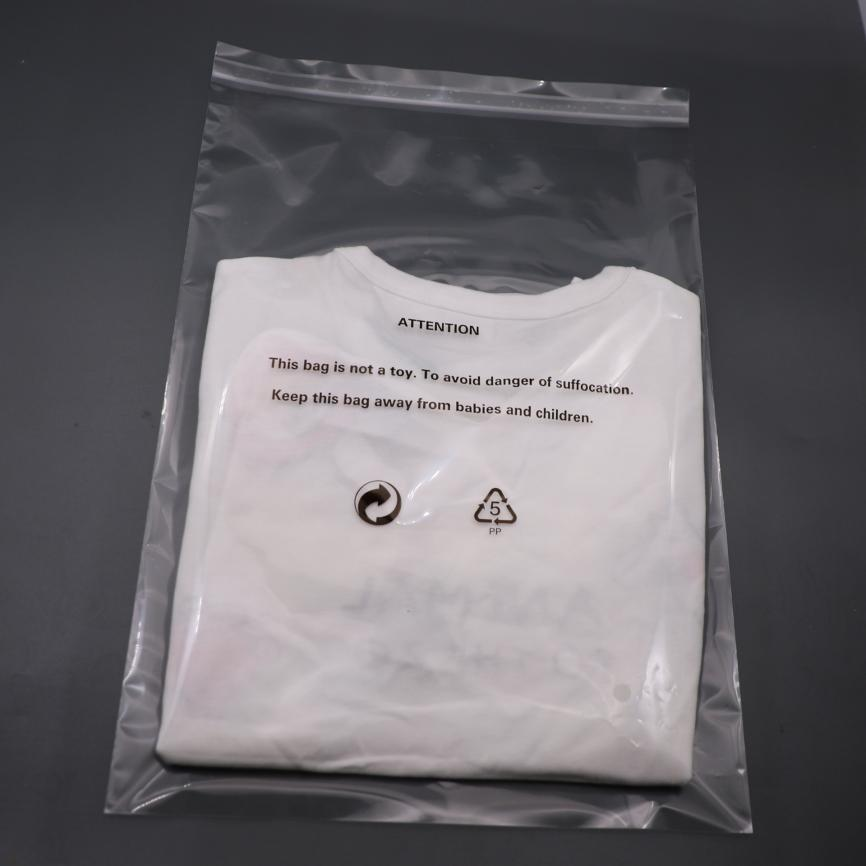

1. Identification by Labeling: Authentic PP food contact products will be labeled with a triangular recycling symbol (with a "5" inside, indicating PP material) and accompanied by food contact information (or FDA-approved). Baby products also require additional prominent labeling, such as "For Infants and Toddlers" and "Plasticizer-Free."

2. Identification by Bulk Density: If a plastic bag is placed on the bottom of water, polypropylene and polyethylene will float, as they have a lower bulk density than water. These bags are non-toxic. Polyvinyl chloride and polystyrene, however, will sink, as they have a higher bulk density than water. These bags are toxic.

3. Identification by Appearance: Non-toxic plastic products, such as polypropylene and polyethylene, are relatively soft, resist breaking when stretched, have a smooth surface, clear printing, and are essentially transparent. Polyethylene, on the other hand, is milky white, and polypropylene is white. Toxic plastic products, such as polyvinyl chloride, have a slightly yellowish tint, are less flexible than polyethylene and polypropylene, and have a slight plasticizer odor.

Is polypropylene recyclable?

In addition to its safety, polypropylene's recyclability is another factor contributing to its popularity in the modern packaging industry. Compared to multi-layer composite plastics or chlorine-containing plastics, PP is easier to separate and reuse during the recycling process, and can be mechanically recycled into new packaging materials or other industrial products.

Furthermore, polypropylene production consumes relatively little energy, and combustion produces only carbon dioxide and water, minimizing its environmental impact. With the increasing popularity of green packaging concepts, PP has become a preferred material for flexible packaging, balancing environmental performance with performance.

In flexible packaging applications, many companies are increasingly adopting mono-material PP packaging to improve recycling efficiency and reduce their carbon footprint. This innovative design not only meets product protection requirements but also aligns with the sustainability goals of international brands.

What will you gain by choosing MTPAK's polypropylene flexible packaging?

For food brands and retailers, choosing safe and compliant polypropylene flexible packaging is not only crucial for meeting regulatory requirements but also for maintaining consumer trust. Leveraging years of experience in flexible packaging solutions, MTPAK has established a comprehensive safety system encompassing "raw materials - process - testing" to provide customers with reliable PP flexible packaging solutions.

1. Raw Materials: We select food-grade materials and reject recycled materials and harmful additives.

For raw material procurement, we partner with globally renowned PP granule suppliers. All raw materials are virgin food-grade and come with detailed analysis reports to ensure they are free of harmful substances such as plasticizers and heavy metals. We also implement a strict additive control policy, using only FDA-certified food-grade additives (such as antioxidants and anti-blocking agents). The added amounts are strictly controlled below the standard to avoid the risk of migration caused by excessive amounts.

2. Process: We utilize fully enclosed cleanrooms to prevent secondary contamination.

MTPAK's PP flexible packaging production line operates in a Class 10,000 cleanroom to prevent dust and microbial contamination. MTPAK is committed to exploring cutting-edge technology and employs innovative packaging and printing techniques to meet the diverse packaging and printing needs of our customers.

3. Multiple Testing for Strict Quality Control

Each batch of products undergoes triple testing: raw material testing, sampling testing during production, and finished product testing. Upon arrival, each batch of PP granules is tested for melt index, density, and hazardous substance content. During production, sampling is tested for PP film thickness, barrier properties, and tensile strength. Before shipment, finished products undergo migration testing (simulating acidic and oily food environments), odor testing, and seal testing. This rigorous quality control ensures that your goods meet safety standards.

4. Customized Flexible Packaging Solutions to Meet Different Scenario Needs

MTPAK can match PP flexible packaging to your product's specific needs. You can choose standard PP packaging or custom-designed PP flexible packaging. Material, bag type, size, and craftsmanship are all customizable.

Conclusion

Polypropylene plastic itself is not a toxic material. On the contrary, compliant polypropylene products are a safe choice for food packaging. The real risks come from inferior raw materials, harmful additives, and improper use.

For businesses, choosing a reliable, flexible packaging supplier is key to mitigating polypropylene plastic safety risks. MTPAK prioritizes safety and rigorously controls every step, from raw materials to finished product, ensuring customers can package and sell their food with confidence.

If you're looking for safe, compliant, and suitable polypropylene flexible packaging, or have questions about the safety of PP materials, please contact MTPAK. We will provide free material samples, compliance reports, and customized packaging solutions, ensuring every PP flexible packaging product earns brand trust.

Email:account@mtpak.com

Contact us:https://mtpak.com/contact-mtpak